- Packing - Handling - Logistics

- Packing and Packaging

- Screw capping machine

- Shanghai Paixie Packing Machinery Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

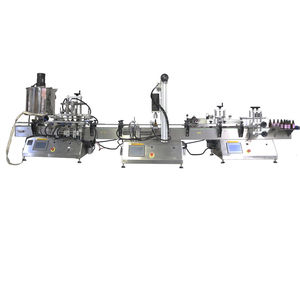

Capper with crimping machine PX-CP50screwPLC-controlledjar

Add to favorites

Compare this product

Characteristics

- Type

- screw

- Operating mode

- PLC-controlled

- Product applications

- jar

- Other characteristics

- with crimping machine

Description

1. Mainly used for aluminum crimping capping of glass jars. The whole machine supports PLC control, with a fiber optic detector deployed at the bottle inlet position. The number of bottles would be counted automatically and the machine would stop operation if there is no bottle.

2. The screw as well as bottle inlet and outlet positions are all equipped with overload devices. The machine would stop operation and send an alarm when bottles are overturned or jammed. The touch screen would automatically display the malfunctioning location to help the users perform troubleshooting as soon as possible.

3. The frame keel of the machine is made of stainless steel square tube. The alarm light can be added to protect the glass cover and exhaust device.

4. Having undergone heat treatment, the cap rolling head has a high sealing qualification rate, stable performance and long service life, and can be used for the packaging lines of oral liquid, liquor, beverage, and condiment.

5. The screw dials all adopt a module-based design. The cap rolling requirements could be met by replacing components, and the height of the cap rolling mechanism could be adjusted manually to adapt to bottles of different heights.

Catalogs

No catalogs are available for this product.

See all of Shanghai Paixie Packing Machinery Co., Ltd.‘s catalogsOther Shanghai Paixie Packing Machinery Co., Ltd. products

Capper

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Filling system for the chemical industry

- Side labelling machine

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

- Weight filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.