- Industrial machines and equipment

- Surface Treatment Equipment

- PVD deposition machine

- Shanghai Royal Technology Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

PVD deposition machine RTAC2000sputteringmetalized filmvacuum

Add to favorites

Compare this product

Characteristics

- Method

- PVD

- Technology

- sputtering

- Deposition type

- metalized film

- Other characteristics

- vacuum

Description

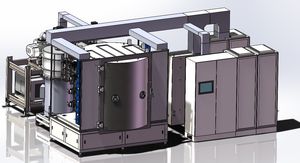

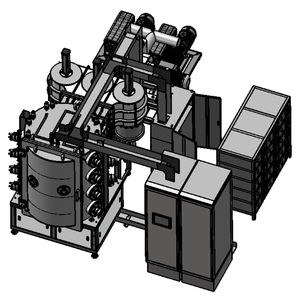

Brass Alloy Security Locks Parts PVD Coating, Metal Locks TiN gold Plating System, Zinc Alloy PVD Coating Machine

Arc Ion Plating Machine particularly used in metals and stainless steel, brass products for a high finishing surface treatment. It gives high shiny and extremely beautiful finishing. The targets always TiAl alloy material or Gold alloy with reactive gas Nitrogen.

It applied with our industrial applications for daily houseware, architectural building materials, jewelry, watches, bathroom fittings, tableware, electronic metal products etc.

Features: fast deposition, strong adhesion, bright colors, easy operate and low power consumption for a beneficial coating service.

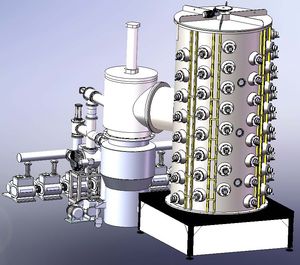

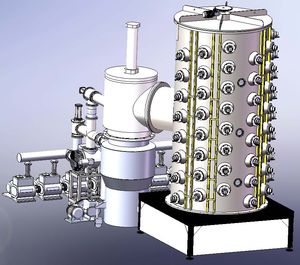

1. Vacuum chamber is vertical one open door , 304 stainless steel manufactures, vacuum chamber internal diameter from φ800mm-Φ2200mm;

2. Vacuum system by Rotary vane pump, Roots pump and Oil Diffusion Pumps or Molecular Pump Constitution;

3. Coating system uses 1-2 intermediate frequency magnetism to control the sputtering power source, has 1-2 pair of non - balanced magnetism to control the target, and has 6-40 arc sources.

4. High efficiency pulse bias power source;

5. The gasification system uses domestically produced or the import gaseous mass flowmeter, the gas flow amount control (demonstration) meter;

6. The electrically controlled system establishment electric circuit overloaded, cuts off the water supply, dies the acousto-optics alarm device;

7. Control system (touch-screen +PLC), real time display detailed parameter, completely automatic control entire production process, and automatic memory technological parameter

Catalogs

No catalogs are available for this product.

See all of Shanghai Royal Technology Inc.‘s catalogsOther Shanghai Royal Technology Inc. products

Cathodic Arc Deposition Equipment

Related Searches

- Coating machine

- PVD deposition machine

- Vacuum deposition machine

- Thin-film deposition machine

- Metalized film deposition machine

- Arc evaporation deposition machine

- Thermal evaporation deposition machine

- Deposition machine for the microelectronics industry

- Automotive deposition machine

- CVD deposition machine

- Short-cycle deposition machine

- Glass coating deposition machine

- Ion beam-assisted deposition machine

- Online deposition machine

- Deposition machine for photovoltaic applications

- PECVD deposition machine

- Sputtering coating machine

- Deposition machine with rotating cathodes

- Medical deposition machine

- Laboratory coating machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.