- Industrial machines and equipment

- Surface Treatment Equipment

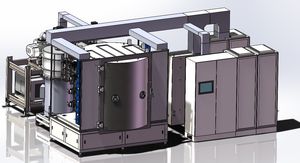

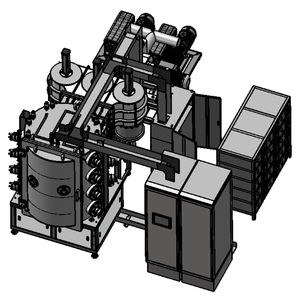

- PVD deposition machine

- Shanghai Royal Technology Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

PVD deposition machine RTAC1008sputteringarc evaporationthin-film

Add to favorites

Compare this product

Characteristics

- Method

- PVD

- Technology

- sputtering, arc evaporation

- Deposition type

- thin-film, metalized film

- Other characteristics

- vacuum, short-cycle, online

- Applications

- for glass coatings, for mirrors, automotive

Description

Advanced production machineries (milling, welding,cutting,vacuum leak testing)combined with standardized production procedures and strict tests enable Royal Technology to produce high quality, reliable and low cost coating systems.

Quality, service and on-time delivery are the core principles of Royal technology’s business. A strategy of openly outsourcing simple components to professional manufactures allows us to focus attention to key parts and components R&D, manufacturing.

Strict quality control policies and rigorous selection of qualified suppliers assure Royal Technology’s customers receive the most advanced, high-end quality equipment at the most affordable cost.

General Infomration:

The PVD ion plating machine is a high efficiency and 100% completely environmentally friendly surface treatment, which generate various colors on the products by solid metal targets and reactive gases.

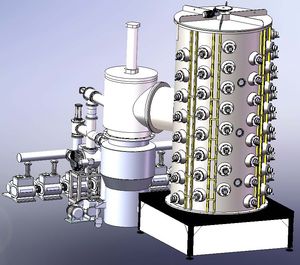

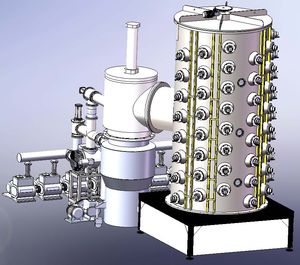

The high vacuum cathodic arc vacuum coating machine has features of fast deposition, high ionization rate, strong adhesion, droplets less advantages.

Our exclusively vacuum pumping system design concept has low power consumption, which reduce 30%~50% production cost per hour.

Patented Cathodic Arc Power Supply developed for minimize this disadvantage : macroparticles (droplets)formation.

The Cathodic arc power supply has DC and Pulsed models, stable arc current; accurate current control with low overshoot.

Cathodic Arc source exclusively designed and produced for maximize the targets utilization ( up to 90% for a some targets)

Bias Power Supply and Ion Source Unit for optional enables a bright colors of final finishing.

VIDEO

Other Shanghai Royal Technology Inc. products

Cathodic Arc Deposition Equipment

Related Searches

- Coating machine

- PVD deposition machine

- Vacuum deposition machine

- Thin-film deposition machine

- Metalized film deposition machine

- Arc evaporation deposition machine

- Thermal evaporation deposition machine

- Deposition machine for the microelectronics industry

- Automotive deposition machine

- CVD deposition machine

- Short-cycle deposition machine

- Glass coating deposition machine

- Ion beam-assisted deposition machine

- Online deposition machine

- Deposition machine for photovoltaic applications

- PECVD deposition machine

- Sputtering coating machine

- Deposition machine with rotating cathodes

- Medical deposition machine

- Laboratory coating machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.