- Industrial machines and equipment

- Surface Treatment Equipment

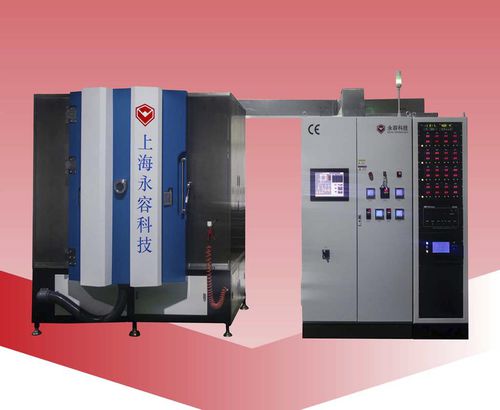

- PVD deposition machine

- Shanghai Royal Technology Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vacuum deposition machine PVD-Ni1600PVDsputteringthin-film

Add to favorites

Compare this product

Characteristics

- Method

- PVD

- Technology

- sputtering

- Deposition type

- thin-film, metalized film

- Other characteristics

- vacuum, short-cycle

- Applications

- for the microelectronics industry, automotive, for photovoltaic applications

Description

The vehicle systems pursuing fuel efficiency, lightweight, emission reduction and design flexibility, when come to material’s selection, compared with metal, engineering plastic shows its advantages and unlimited potential. The PPS is so special because they contribute significantly to the qualify of life on automotive industry with theirs versatile properties: more efficient and safer, more comfortable and more beautiful; unlimited on design ideas and forming process, more flexible.

PVD direct plating on PPS Plastic

Nickel electroplating on PPS which has been accomplished using a traditionally Palladium / Tin colloidal-type activation system with electroless chemical treatment, this process is called roughening.. While increasing stringent environmental conditions as well as substantial cost reductions called for by the automobile industry have forced the electroplating industry to look for techniques such as direct metallization processes .

In year of 2019, we received a request from our local customer who is providing the electroplating services for automotive plastic components. “Is that possible to coat Ni directly on engineering plastics to replace the electroless process and make the Palladium-Free?” asked Mr. Woo the owner of JS company.

Royal Technology spent 6 months to made experiments and successfully developed the proper coating process and the result satisfy customer’s quality testing terms. The direct metallization layer makes the plastics transit from non-conduction to conductive and then get post-treatment with Cu/Ni/Cr electroplating process.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Royal Technology Inc.‘s catalogsOther Shanghai Royal Technology Inc. products

Innovative Custom PVD Machine

Related Searches

- Coating machine

- PVD deposition machine

- Vacuum deposition machine

- Thin-film deposition machine

- Metalized film deposition machine

- Arc evaporation deposition machine

- Thermal evaporation deposition machine

- Deposition machine for the microelectronics industry

- Automotive deposition machine

- Short-cycle deposition machine

- Glass coating deposition machine

- Ion beam-assisted deposition machine

- Online deposition machine

- CVD deposition machine

- Deposition machine for photovoltaic applications

- Sputtering coating machine

- Deposition machine with rotating cathodes

- PECVD deposition machine

- Vacuum coating machine

- Laboratory coating machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.