- Products

- Vacuum coating machine

- Shanghai Royal Technology Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

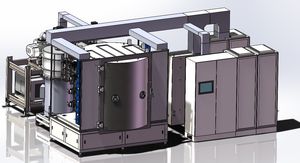

Vacuum coating machine RTAC1200A+

Add to favorites

Compare this product

Description

Metal door handles and security locks are usually made of Zamak (Zinc Alloy) or Aluminum Alloy, brass alloy. It requires a high quality of beautiful final finishes with various colors.

PVD Ion Plating technology has used so well in this application.

After proper surface pre-treatment before PVD coating, like polishing, brushing, or sandblasting; the PVD plating system gives various colors. The deposited films are pure metal or multiple layers like TiN, TiC, ZrN, CrN,TiAlN, with bright colors, strong adhesion & excellent scratch protection, fast deposition rate, good diffraction.

PVD finish properties

Exceptional aesthetic finish

Uniform coating thickness and colors

Superior resistance to wear and corrosion

PVD coating has a high level of hardness

PVD coating is not discolor or tarnish with a proper daily take care

PVD finishes available

Brushed PVD colors

Mirror PVD colors

Matte PVD colors

Gold, rose gold, brass, charcoal grey, graphite black, bronze, blue, white Chrome, black nickle, stainless steel finishes, blue etc.

Catalogs

No catalogs are available for this product.

See all of Shanghai Royal Technology Inc.‘s catalogsOther Shanghai Royal Technology Inc. products

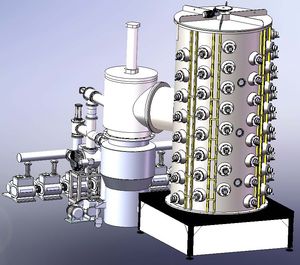

Cathodic Arc Deposition Equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.