- Production Machines

- Forming Machine

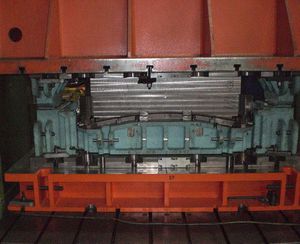

- Hydraulic press

- Sheet Metal Men s.r.l.

Hydraulic press SMO / SMCO seriesdeep drawingPLC-controlledvertical

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- deep drawing

- Control

- PLC-controlled

- Other characteristics

- vertical

- Applications

- for sheet metal

- Force

Max.: 4,000 kN

Min.: 400 kN

- Opening

Max.: 1,300 mm

(51 in)Min.: 700 mm

(28 in)

Description

The structure is made in thick steel plate, welded, stress relieved and shot-blasted.

The cylinders, made out of special steel, have guides of bronze and the pistons rods are case-hardened and chromium-plated.

The slides are guided by self lubricating wear plates sliding on steel guides.

The hydraulic group is mounted up the oil tank. It's equipped with:

- Main-motor pump unit and one block of control valves.

- Auxiliary device for actuate the filter and the oil cooler.

The regulations of the slide stroke, TDC (top dead centre), braking position and BDC (bottom dead centre) are made with PLC, encoder with wire unit and digital control with display.

The presses have hydraulic system to hook the slide at TDC and timer to regulate the coining time.

The electric cabinet contains all the necessary components for the control of the machine, protection of motors, security circuits and controls and PLC.

The operator comand the machine with a two hand control pulpit.

Safety photoelectic barriers.

The presses work with two cycles:

- Manual cycle with slow speed and single indipendent movements for the set-up of the machine.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Sheet Metal Men s.r.l.‘s catalogsRelated Searches

- Industrial press

- Hydraulic press

- Forming press

- Assembly press

- Vertical press

- Stamping press

- Drilling press

- PLC-controlled press

- Cambering press

- Roll forming line

- C-frame press

- Hot press

- Sheet metal press

- Drawing press

- Profile roll forming line

- Deep drawing press

- Automatic roll forming line

- Edge-trimming machine

- Press with pressure regulator

- Roll forming line with cutting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.