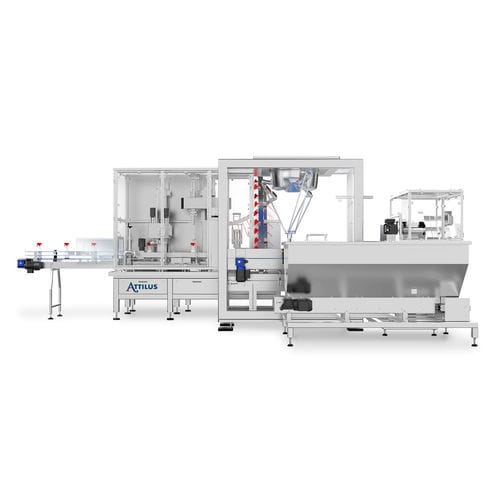

ATTILUS is a versatile high speed automatic capping machine which utilises the latest robotic technology to offer faster, enhanced accuracy in automatic caps, pumps and triggers sorting.

How it works

A Robotic Sorter based on Delta Robot and an advanced vision system allows the ATTILUS to sort and orientate caps from the most complex screw tops to trigger and pump caps.

Also, the ATTILUS utilizes a pick & place Cartesian Robotic Arm (gantry two axis robot), which is servo-controlled, to track and deliver the caps to the bottles while in motion, ensuring smoother and faster production.

Common Applications

Fixes Triggers, Pumps, Screw Caps and more

Applicable to all common bottle shapes and sizes.

Benefits:

Up to 80 products per minute

Different cap types and formats are changeable at the touch of a button!

Almost eliminates the need for format parts

Dramatically reduces downtime (under 20 minutes changeover)

Servo controlled torque QC and cap position QC

Much more!