- Environment - Health - Safety

- Building Security and Machine Safety

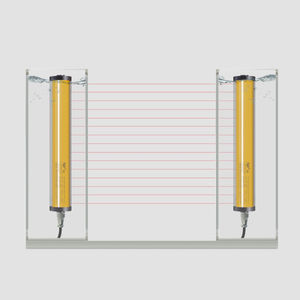

- Safety light curtain

- Shenzhen ESPE technology Co., LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

Safety light curtain ELV seriesmultibeamthrough-beaminfrared

Add to favorites

Compare this product

Characteristics

- Function

- safety

- Type of beam

- multibeam

- Configuration

- through-beam

- Other characteristics

- infrared

- Operating range

Min.: 0.1 m

(0'03" )Max.: 20 m

(65'07" )

Description

Features:

1.Reinforced installation brackets adopted, good anti-shock performance, durable.

2. Multi-type of controllers and installation brackets can be chosen.

3. High quality components adopted, with high safety performance and stability.

4. Already passed the national test standard, certificated with utility model patent.

5. One controller can control multi-pairs of sensors.

6. In accordance with GB4584-2007 Technical Standards and Regulations of

National Quality Supervision and Test Center of Casting and Forging Machinery.

1. Working Principle.

Normally the emitter of light curtain emits infrared light straightly to the receiver and that will form a protection curtain. When a opaque object enters into the protection zone, the light curtain will be interrupted. Then a control signal will be generated and transmitted to the control circuit and other alarm equipment, realizing the machine tool??s stop or alarm.

Remarks :

a. Customers can choose controller and bracket according to requirements. The standard conguration of controller to ELV series is X type and the bracket is J type.

b. Standard con?guration of signal cables are two, 2.5 meters and 3.5 meters respectively.

c. Installation model can be customized, including lengthening the cables or changing the installation method, etc.

d. Power Voltage 24/ 380 V can be customized.

Application

Well applicable to large-tonnage machines with high speed impact and huge shake, such as punching machine, plate shearing machine, wheel-type punching machine and press brake, etc.

Other Shenzhen ESPE technology Co., LTD products

Safety Light Curtain

Related Searches

- Light barrier

- Multibeam light barrier

- Safety light barrier

- Through-beam light barrier

- Waterproof light curtain

- IP65 light barrier

- Infrared light barrier

- Hand protection light curtain

- Compact light barrier

- Measuring light curtain

- Frame light barrier

- Access control light curtain

- Explosion-proof light curtain

- IP68 light curtain

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.