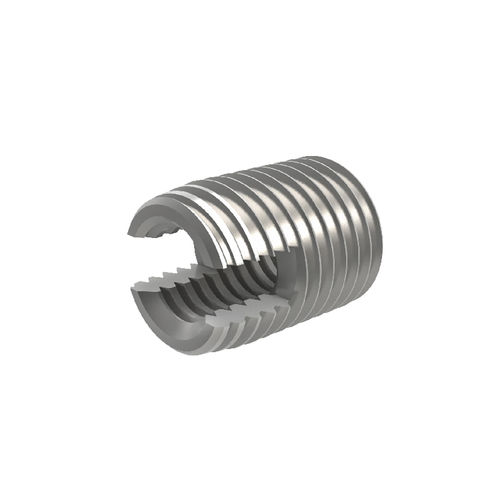

Thread specification: M2-M30

Common materials: stainless steel, carbon steel, brass, etc

Other specifications can be customized according to customer's requirements.

Installation Method

Installation method of self-tapping screw sleeve 1: When the number of installations is small, a simple installation method can be adopted, specifically, the method of bolts + nuts of corresponding specifications is adopted, the self-tapping screw sleeve is fixed on the bolts of corresponding models, and the nuts of the same models are fixed to make the three become a whole, then the screw sleeve is screwed into the bottom hole with a wrench, and then the bolts are withdrawn.

Simple Installation Method of Self-tapping Screw Sleeve

Installation Method 2 of Self-tapping Screw Sleeve: When the number of installations is large, Special self-tapping screw sleeve installation tools can be used. First, the self-tapping screw sleeve is installed on the special tool, and the tool with the screw sleeve installed is screwed into the prefabricated hole for about one turn. After ensuring that the tool is perpendicular to the end face of the prefabricated hole, the screw sleeve is screwed in with force. When the end face of the self-tapping screw sleeve is about 0.2 mm lower than the end face of the prefabricated hole, stop screwing in and screw out the special tool in reverse. The tail end of the self-tapping screw sleeve installation tool is a hexagonal head, which can be connected with manual tapping wrench or electric or pneumatic tools.