- Industrial machines and equipment

- Welding and Assembly

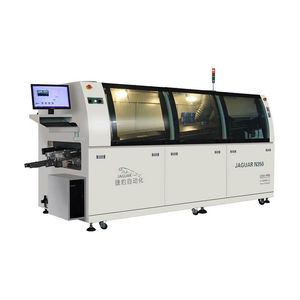

- Wave soldering machine

- Shenzhen Jaguar Automation Equipment Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Wave soldering machine Top-350PC-controllablePLC-controlledmulti-zone

Add to favorites

Compare this product

Characteristics

- Technique

- wave

- Operating mode

- PC-controllable, PLC-controlled

- Other characteristics

- multi-zone

- Power

Max.: 20,000 W

Min.: 8,000 W

Description

DIP lead free Wave Soldering Machine

Name: N450 wave soldering machine

Model: Top-350

Brief: JAGUAR high-end lead-free wave soldering machine with high precision and stability

Introduction:

Top series wave soldering design si degitalized, module defined, and human-oriented, it shows superiority in function, performance, stability, reliability, safety, maintainability, operability and humanization. It can not only reduces customers’ operation cost, and also provides an effective guarantee in quality and quantity during production. It is the “Peak work” of wave soldering industry and the preferred brand for customer investment.

1. Closed Loop control with Inverter control system to keep the stability and accuracy of speed managed.

2. The transmission structure adopts double row column quick change claw, and has strong adaptability to various PCBs.

3. With independent temperature control in 4 Pre-heating zones that can insure to achieved the best heat-efficiency.

4. Modularization high efficiency pre-heater is convenience for maintanance, attained powerful heat and long life.

5. The nozzle is right angle according to rail always to ensure the flux can good penetrate the PCB through holes.

6. Solder wave can be started automatically according to the PCB’s conveyor. Height of dancer wave and laminar wave are controlled separately by inverter.

7. Circular arc appearance, environmental protection design.

8. PC and PLC controller constitute a perfect and stable control system

9. Powerful software features, PCB board online temperature measurement, and at any time to print and save the temperature curve, easy to learn control software, a few minutes can learn to operate.

Other Shenzhen Jaguar Automation Equipment Co., Ltd. products

DIP lead free Wave Soldering Machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.