- Packing - Handling - Logistics

- Packing and Packaging

- Automatic strapping machine

- Shenzhen Packway Technology Development Co., LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

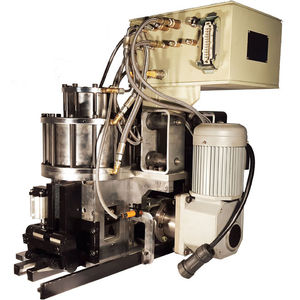

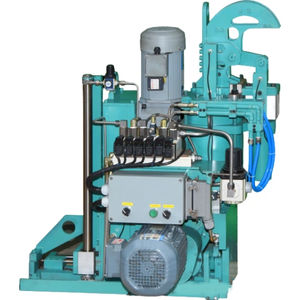

Automatic strapping machine DGR-ⅢAcoilfor woodpipe

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Product applications

- coil, for wood, pipe, for profiles, bar, sheet metal, for aluminum, for waste, for waste

- Type of strap

- for steel straps

- Power supply

- 380V three-phase

- Other characteristics

- vertical, motorized

- Strap width

19 mm, 25 mm, 32 mm

(0.748 in, 0.984 in, 1.26 in)- Strip thickness

Max.: 1.2 mm

(0.05 in)Min.: 0.8 mm

(0.03 in)- Power

1 kW, 2.2 kW

(1.36 hp, 2.99 hp)

Description

Coil Strapping Machine/Packing Solutions For Metal Industry:

Friction Welding Type Bundling Machine Head can keep 5% tightening force for a long time without back to loose, and there is 5% buffer extension rate to ensure the safety of the packages. Pet strapping does not have sharp edges, so it will not damage the packaged objects, and at the same time, it will not cause any harm to the operators in the process of packing.

Friction welding type automatic PET belt strapping machine head

Pressure: 4-6 bar, Max instantaneous gas consumption: Max 0.9L/s

Strapping speed

General working time of head in strapping process is 9.8 seconds/belt;

Belt connection

Instantaneous welding at overlapping PET belts using the principle of friction heating

Belt tension

Max. (adjustable)

Consumable accessories list

Feeding—belt wheel, Belt cutter

Machine maintenance

Suggest providing minor maintenance every six months and major maintenance every year

Daily maintenance

As per general equipment maintenance

Applicable environment

Normal temperature environment, suitable for ultrasonic welding

Applicable objects

Galvanized coil, cold rolled coil, steel pipe pile, profile pile, bar pile, sheet pile, aluminum ingot pile, steel ingot pile, pipe pile, wood pile, waste pile, etc

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shenzhen Packway Technology Development Co., LTD‘s catalogsOther Shenzhen Packway Technology Development Co., LTD products

Coil Strapping Machine

Related Searches

- Packing machine

- Automatic packing machine

- Automatic labelling machine

- Strapping machine

- Automatic strapping machine

- Film packing machine

- Side labelling machine

- Packing machine with sealing

- Vertical strapping machine

- Packaging labelling machine

- Fully-automatic strapping machine

- Cardboard box strapping machine

- Horizontal strapping machine

- High-speed strapping machine

- 380V three-phase strapping machine

- Coil strapping machine

- Bundle strapping machine

- Fold wrapping packing machine

- Coil packing machine

- Motorized strapping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.