- Industrial machines and equipment

- Printing, Marking and Engraving

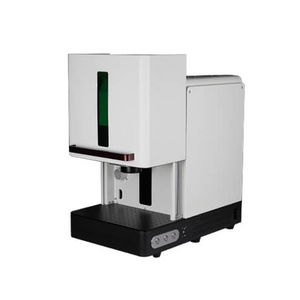

- UV laser marking machine

- Shenzhen triumph industrial co.,ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

UV laser marking machine metalglass

Add to favorites

Compare this product

Characteristics

- Technique

- UV laser

- Material

- metal, glass

Description

UV LASER MARKING MACHINE

Purple light UV laser marking machine takes 355nm pumped purple light laser device as the light source and takes advantage of previous generations machine to gain smaller diameter of focusing spot and fine marking effect. The metal absorb purple light higher than infrared and therefore more suitable for marking on metal and glass materials compared with infrared pump machine. Narrower pulse width of laser makes a shorter time of processing on materials, thus the materials avoid being deformed or burnt due to thermal. With smaller heat affected area and more beautiful marking effect, our products can meet customer’s demand of higher marking requirements.

FEATURES OF UV LASER MARKING MACHINE

(1) Adopting doubling technique of intravenous frequency has greatly improve the stability of laser. Design on laser cavity adopts a series of optimization method, so as to ensure the beam quality as the fundamental mode.

(2) The machine takes 355nm pumped purple light laser device as the light source. Narrower pulse width and smaller heat affection contribute to generate peak power. The higher the peak power is, the wider the adapting range of materials is. This implement perfect printing in some relatively hard material.

(3) Higher pulse stability, namely better pulse consistency of laser produces the same carving effect, so it’s very suitable for precision marking. Higher pulse repetition frequency meets the need of quick marking and high production efficiency.

(4) High efficiency of the photoelectric conversion and long service life.

(5) It can support logos and graphs designed in DXF format from Auto-CAD, PLT, BMF, AI, JPG, etc.

Other Shenzhen triumph industrial co.,ltd products

Laser Marking System

Related Searches

- Marking machine

- Laser marking workstation

- Metal marking workstation

- Benchtop marking workstation

- Plastic marking workstation

- High-speed marking machine

- Compact marking workstation

- Fiber laser marking machine

- Laser engraving system

- Air-cooled marking machine

- Hand-held marking machine

- Electronic component marking machine

- Wood engraving machine

- CO2 laser marking machine

- Paper marking machine

- Glass engraving machine

- Wood marking machine

- Plastic engraving machine

- Metal engraving system

- Glass marking machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.