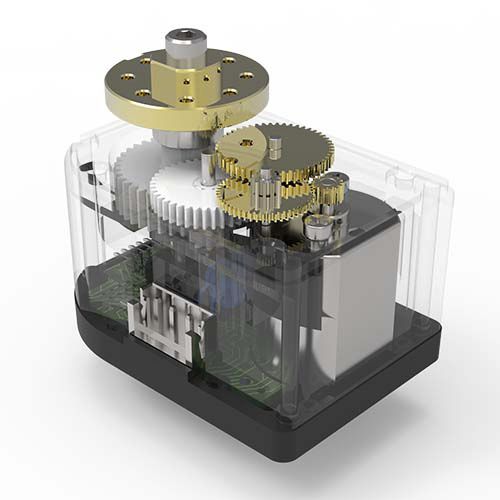

Material : Plastic/Metal

Voltage : 4-7V (customizable)

Load Current : 250mA

Rated Speed : 5-2000rpm

Reduction Ratio : 5-1500

Noise : ≤42db

The servo motor for the model airplane is designed and developed for designated customers. Below is only the showcase. Besides selling standard products, ZHAOWEI can provide design, research, and manufacture for customers based on their specific needs as well.

The design principle is that the planetary gearhead module drives the rudder plate to rotate. The control circuit board receives the control signal from the signal line and controls the rotation of the motor. The motor drives a series of gear sets to decelerate and transmit to the rudder plate. The output shaft of the servo motor is connected to the position feedback potentiometer. The position feedback potentiometer is driven while the rudder plate rotates. The potentiometer will output a voltage signal to the control circuit board for feedback, and then the control circuit board will determine the rotating direction and speed of the motor according to the position, thus stopping the target.

When the aircraft model needs to tilt, the servo motor is manipulated to tilt, and the swash plate connected to the servo motor through the tie rod immediately tilts. At the same time, the steering wheel arranged on the swashplate, the main propeller linked to the steering wheel, and the lower plate linked with the main propeller, the upper plate arranged on the lower plate, and the auxiliary propeller linked with the upper plate also tilt synchronously to change the tilt direction and complete the tilting action.