- Machine-tools

- Machining Center

- CNC milling-turning center

- Shibaura Machine

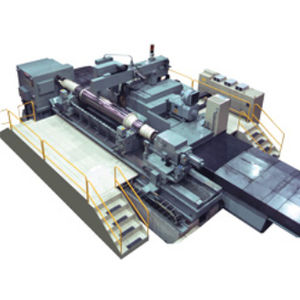

CNC milling-turning center MP-2620(U)vertical5-axisdouble-spindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- vertical

- Number of axes

- 5-axis

- Structure

- double-spindle

- Other characteristics

- high-productivity, high-speed, high-rigidity

- X travel

2,500 mm

(98.43 in)- Y travel

3,400 mm

(133.86 in)- Z travel

800 mm

(31.5 in)- Spindle power

22 kW, 26.5 kW

(29.91 hp, 36.03 hp)- Spindle speed

Max.: 10,000 rpm

(62,831.853 rad.min-1)Min.: 40 rpm

(251.327 rad.min-1)

Description

SHIBAURA'S ADVANCED TECHNOLOGIES have been focused on our bridge type multi-purpose machine.

Main features

Machining center, vertical turning center, and as a 5 axis machine when selecting the optional spindle head. The overall design of this machine is an integral feature to also process an extensive range of machine parts.

"All linear axis X, Y and Z are designed with twin drive mechanism in order to achieve high rigidity and high accuracy. This attribute allows swift machine motion even at 40m/min in rapid and 20m/min in cutting feed mode."

Features of the machine

Axis configuration

The standard machine has 4 axes which consist of three (3) linear axes of X, Y, and Z, and one (1) rotary axis C.

A 4-axis head in an (optional accessory) for 5-axis machining.

The W axis is a crossrail that can be located at 5 positions is 250mm increments.

Productivity

Several kinds of attachments make the machine a multi-purpose machine.

The Snout 240 can be used for boring and turning operation as shown in figure 1, and 2.

The angle head can be utilized for machining the side of a workpiece as shown in figure 3.

4-axis head is shown for machining on any inclined surface.

Accessibility

Chip cover with ceiling

The chip cover with ceiling enclosure is standard accessory, and the L-shape door with ceiling compliment an ergonomic design, enabling easy access to the area around the table.

Axcellent chip discharge around a wide enclosure.

Wide space and easy chip discharge around the table

A round rigid table is utilized turning and milling operations for both turning and milling operations.

Catalogs

No catalogs are available for this product.

See all of Shibaura Machine‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-precision turning center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- Turning-milling machine

- CNC turning-milling center

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.