- Machine-tools

- Machining Center

- CNC boring machine

- Shibaura Machine

- Products

- Catalogs

- News & Trends

- Exhibitions

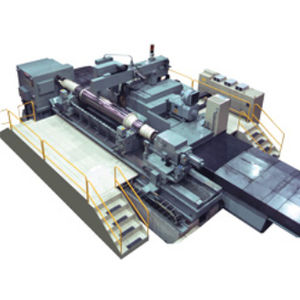

CNC boring machine BSF-150Cverticalhigh-performancehigh-precision

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Other characteristics

- high-precision, high-performance, high-productivity, high-speed

- X travel

Max.: 18,000 mm

(708.66 in)Min.: 4,500 mm

(177.17 in)- Y travel

2,500 mm, 3,000 mm, 3,500 mm, 4,000 mm

(98.43 in, 118.11 in, 137.8 in, 157.48 in)- Z travel

750 mm, 900 mm

(29.53 in, 35.43 in)- W travel (spindle)

750 mm, 900 mm

(30 in, 35 in)- Spindle diameter

150 mm

(6 in)- Power

30 kW, 37 kW

(40.78863 hp, 50.30598 hp)

Description

This new model has been re-engineered in regard to performance and design to respond to the market's need for higher speed and accuracy

Good accessibility

A total extension of W and Z axis is 1 800 mm in case of a special option, 380 mm x 380 mm square ram dimension gives optimum accessibility on a deep workpieces

Spindle head gravity center compensating device

The Spindle head-center of gravity compensating device counteracts the primary cause of ram sag which occurs when changing center of gravity as the ram moves out. Tension on two balancing cables, front and rear, are automatically adjusted based on ram position to achieve optimum straightness when extending the ram.

Extensive Attachments (Optional accessories)

Other attachments can be supplied based on customer requirements.

Machine Layout

Versitile Layout with Floorplates

Floor plates provide minimum size and weight restrictions for work pieces and allow flexible work piece set-ups. The example sketch shows three floorplates arranged in lengthwise, in a single row along X-axis travel. Multiple floorplate arrangements are restricted only by available floor space and can be in crosswise or double row depending customers requirements.

Flexible Layout with Floorplates and Rotary Table

A Rotary Table provides great flexibility allowing machining on multiple face workpieces, boring on inverted face and high precision rotary milling and drastically improves productivity. Combined with floor plates, this specification provides flexibility to machine a wide variety of work pieces Multiple arrangements of this layout are available.

Catalogs

No catalogs are available for this product.

See all of Shibaura Machine‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-precision turning center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- Turning-milling machine

- CNC turning-milling center

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.