- Machine-tools

- Machining Center

- CNC boring mill

- Shibaura Machine

- Products

- Catalogs

- News & Trends

- Exhibitions

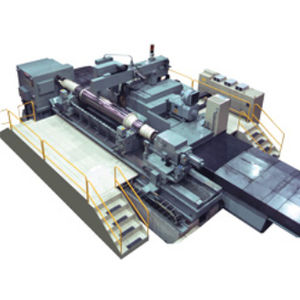

CNC boring mill TUD verticalcolumn type2-axis

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Structure

- column type

- Number of axes

- 2-axis

- Applications

- heavy-duty

- Other characteristics

- high-precision, high-performance, high-rigidity

- X travel

Min.: 630 mm

(24.8 in)Max.: 1,370 mm

(53.94 in)- Z travel

800 mm, 1,050 mm

(31.5 in, 41.34 in)- Power

37 kW, 45 kW

(50.30598 hp, 61.18295 hp)

Description

TUD series of CNC Vertical Boring and Turning Mills for unrivaled efficiency in boring and turning operation

The thick-walled, cast Iron column and be is thermal symmetrically designed for high precision and heavy-duty machining

With an automatic tool-locking mechanism

The 220mm (8.66 in) square ram is solidly encased in a mono box structure which is incorporated with an automatic tool-locking mechanism

For Virtually all workpiece heights

A step positioning mechanism moves the crossrail a maximum 0f 500mm (19.6in) vertically in 250mm (9.84in) steps [750mm (29.5in) for TUD-20] for virtually all workpiece heights

Automation and labor saving

Special options, such as an automatic tool changer (ATC) and an automatic pallet changer (APC) are available for even greater degrees of automation and labor saving

Table and bed

All of the major machine components are constructed of high-grade castings. The table has been provided with ample strength and size and is supported on a largediameter thrust ball bearing and tapered roller bearing arrangement. This type of arrangement assures adequate support fo extremely efficient, high speed heavy machining. In addition, the talbe is equipped with 4 independent manually-operated jaws and T-slots that guide and hold the workpiece in the required position.

Thermal deformation is minimized by the standard-type lubricating-oil cooling system and the thermally symmetric layout of the machine bed which supports the table. Additionally, the table-drive mechanism is built into the rear section of the bed, and column is standing on the bed.

Catalogs

No catalogs are available for this product.

See all of Shibaura Machine‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-precision turning center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- Turning-milling machine

- CNC turning-milling center

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.