- Machine-tools

- Machining Center

- 3-axis machining center

- Shibaura Machine

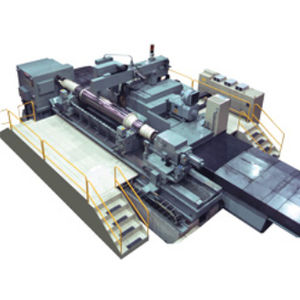

3-axis CNC machining center MPF-F seriesverticaldouble-columnBT 50

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- double-column

- Spindle mount

- BT 50

- Number of tool stations

- 90 tools

- Other characteristics

- high-speed, high-productivity, high-rigidity

- X travel

Max.: 5,500 mm

(216.54 in)Min.: 1,400 mm

(55.12 in)- Y travel

2,100 mm, 2,600 mm, 3,100 mm

(82.68 in, 102.36 in, 122.05 in)- Z travel

715 mm

(28.15 in)- Rotational speed

Max.: 10,000 rpm

(62,832 rad.min-1)Min.: 40 rpm

(251 rad.min-1)- Power

5.5 kW, 7.5 kW

(7.48 hp, 10.2 hp)- Work feed X-axis

20,000 mm/min, 30,000 mm/min

(13 in/s, 20 in/s)- Work feed Y-axis

30,000 mm/min

(20 in/s)- Work feed Z-axis

20,000 mm/min

(13 in/s)- Table load capacity

10,000 kg, 20,000 kg

(22,046 lb, 44,092 lb)- Positioning accuracy

0.007 mm

(0.00028 in)- Repeatability

0.003 mm

(0.00012 in)- Weight

21,200 kg, 23,500 kg, 30,200 kg

(46,738 lb, 51,808.63 lb, 66,579.6 lb)- Overall length

5,150 mm, 5,750 mm, 6,250 mm

(202.8 in, 226.4 in, 246.1 in)- Overall width

4,420 mm, 5,700 mm

(174 in, 224.4 in)- Overall height

5,350 mm

(210.6 in)

Description

Double column type machining center best suited for high-speed and high efficiency machining operations

Main feature

Most sophisticated energy-saving machine, fully considering resources and environment

Sharp cut in air consumption.

Complete elimination of oil mist scattering into the air.

Energy-saving Z-axis twin ball screws, not requiring any balancing unit.

Cartridge spindle, considering easy maintenance

190mm-diameter long nose satisfying both easy access and heavy-duty cutting"

Wide machining range and small installation space

In spite of the machine whose distance between columns is 2100mm, the installation space is as small as 20m2, which is smaller than the vertical machining center having equivalent machining range.

A basis for machine rigidity is provided by integrally cast column and crossrail characterized by high rigidity (π Frame)

Angle Head (Option)

The optional angle head extend machining capability on the MPF series machine to five-side on a workpiece in order to increase machining efficiency on her.

The machine is able to work on four-side of workpiece with the optional angle head, in addition to work on top face with the standard snout, in single set-up.

Maximum power : 3kW at 100 min-1

Maximum torque : 286N・m(29kgf・m)

Maximum speed : 2000min-1

Tool change : AATC

(An optional special tool changer with AATC feature is required)

Catalogs

No catalogs are available for this product.

See all of Shibaura Machine‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- High-rigidity CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- Turning-milling machine

- CNC turning-milling center

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.