- Hydraulics - Pneumatics

- Pump

- Slurry pump

- Shijiazhuang Sunbo Pump Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

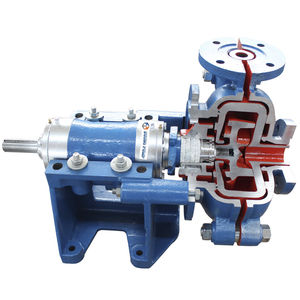

Slurry pump HS seriesdiesel enginecentrifugalindustrial

Add to favorites

Compare this product

Characteristics

- Fluid

- slurry

- Operation

- diesel engine

- Technology

- centrifugal

- Domain

- industrial

- Fluid specification

- for abrasive fluids

- Other characteristics

- single-stage, horizontal mount

Description

The slurry pump is a type of centrifugal pump, designed for pumping liquid containing solid particles in mining, metallurgy,coal washing ,sewage water treatment,power plant,dredging.and chemical and petroleum industries etc

The HS series pumps are designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements, the horizontal centrifugal pumps will maintain high efficiencies over the wear life of its components. The rubber and metal lined pumps feature casings which are radially split into two halves. Minimum casing bolts reduce maintenance and minimise downtime.

Features:

Bearing assembly---A large diameter shaft with short overhang minimizes deflection and contributes in to long bearing life. Only flour through bolts are required to hold the cartridge type housing in the frame.

Liners---Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

Impeller---Front and rear shrouds have pump out vanes that reduce re-circulation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts.

Throat bush---Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Specification:

Size range (outlet)

1" to 18"

25 mm to 450 mm

Capacities

to 22,000 gpm

to 5,000 m³/hr

Head

to 240 ft

to 73 mt

Catalogs

Other Shijiazhuang Sunbo Pump Co., Ltd products

Slurry Pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.