- Machine-tools

- Machining Center

- CNC lathe

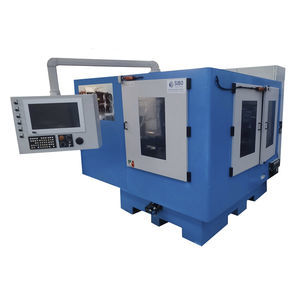

- SIBO engineering

CNC lathe 4TF/1000horizontalmulti-spindlewood

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- horizontal

- Number of spindles

- multi-spindle

- Applications

- wood

- Associated function

- milling, finishing

- Maximum part length

Max.: 1,000 mm

(39 in)Min.: 200 mm

(8 in)- Maximum cutting diameter

Max.: 80 mm

(3 in)Min.: 20 mm

(1 in)

Description

The CNC lathe 4TF/1000 stands out in the field of milling, revolutionizing productivity with its ability to simultaneously work four pieces. Thanks to its advanced numerical control (CNC) technology, it eliminates the need for traditional templates, paving the way for a faster, more efficient, and more precise production process. Thanks to its advanced numerical control (CNC) technology, it eliminates the need for traditional templates, paving the way for a faster, more efficient, and more precise production process.

The machine is suitable for machining hammer handles, pickaxe handles, axe handles, and chair legs.

It is equipped with eight electro spindles, four of which are dedicated to roughing mills that quickly shape the pieces, while the other four are reserved for finishing mills, perfecting every surface. The operational feature of this lathe is further extended thanks to the four interpolated axes, which allow working the pieces from 2 angles, both laterally and from above, greatly expanding the versatility and precision of the possible workings.

This advanced configuration not only guarantees high-quality pieces but also significantly reduces, or in some cases eliminates, the need for manual finishing interventions like sanding. This means smoother surfaces, tighter tolerances, and a final product quality that stands out in the market.

Catalogs

No catalogs are available for this product.

See all of SIBO engineering‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Drilling machine

- Wood router

- Milling CNC machining center

- Cutting CNC machining center

- Milling machine

- Drilling CNC machining center

- Precision CNC milling machine

- 3-axis milling machine

- CNC drilling machine

- Milling turning center

- Vertical milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.