- Machine-tools

- Machining Center

- 7-axis machining center

- SIBO engineering

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

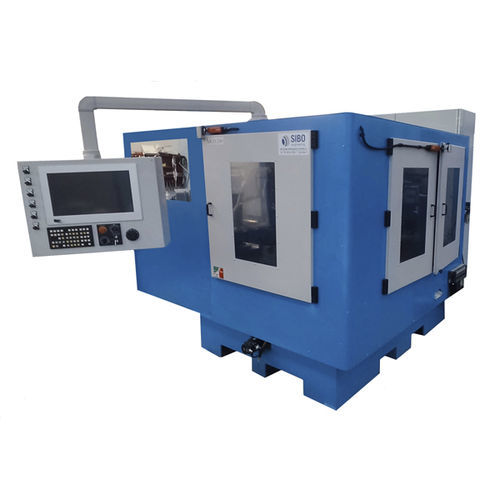

Wood CNC machining center MCD/280 CNC7-axisuniversalmilling

Add to favorites

Compare this product

Characteristics

- Number of axes

- 7-axis

- Spindle orientation

- universal

- Machined material

- for wood

- Associated functions

- milling, cutting, drilling

- Applications

- for the wood industry

- Other characteristics

- with automated loading, for production

Description

The MCD/280 is an advanced CNC automatic machine designed for the production of bricks and various components for wooden toys. The machine is equipped with a 7-axis CNC and features a loader, a cutting unit, two multi-spindle drilling units, 2 vertical spindles, and three aggregates, each with 3 horizontal spindles.

The operator loads the bars into the loader, stacking them one on top of the other. The bottom bar is pushed against a reference plate, and a CNC slide feeds it into the first gripper, where it is clamped and cut to the desired length according to the specified model.

The first gripper, controlled by three interpolated axes, moves the piece under the different operating units, where it is machined on the accessible faces. Once the operations are completed, the piece is transferred to the second gripper where it is completed. At the end of the processing, the first gripper returns to the initial working position to begin the new cycle. This configuration allows the two grippers to work simultaneously on different faces, speeding up the production process.

Catalogs

No catalogs are available for this product.

See all of SIBO engineering‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Drilling machine

- Wood router

- Milling CNC machining center

- Cutting CNC machining center

- Milling machine

- Precision CNC milling machine

- Drilling CNC machining center

- 3-axis milling machine

- CNC drilling machine

- Vertical milling machine

- Milling turning center

- Swiveling-spindle CNC milling machine

- Vertical drilling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.