Integration marking unit FIT LASERlaser

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Other characteristics

- for integration

Description

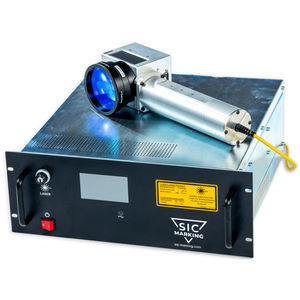

The LASER F.I.T. is A LASER MARKING UNIT WITH A SAFETY SLEEVE, designed for integration into production lines.

This all-in-one integrable solution includes the supply and the protections required to efficiently and safely mark parts on a production line.

The marking unit is particularly COMPACT AND LIGHT (13 kg), for easy integration.

The LASER F.I.T. is actually READY FOR INTEGRATION AS CLASS 1.

For the protection of persons close by, the beam is enclosed in a sleeve that contains the radiation.

Various sizes of sleeve are available, to match your marking sizes and surfaces: 34 mm x 32 mm, 100 mm x 32 mm, 100 mm x 100 mm.

Other sizes are possible on request.

Connecting the LASER F.I.T. to your PLC is extremely simple.

A SINGLE Profinet, Profibus or Ethernet IP type connection provides quick and easy integration.

The LASER F.I.T. has AN INTEGRAL COMPENSATOR that guarantees optimum marking.

This eliminates the need for expensive and fragile electronic autofocusing.

This mechanical autofocusing compensates changes in settings, parts, tolerances or robot arm precision, for an ideal focal length that guarantees perfect marking.

To guarantee performance in the long term, the LASER F.I.T. incorporates specifications and specific accessories that PROTECT and ENSURE THAT THE UNIT OPERATES PROPERLY

in severe production environments, for example, an access hatch for the lens protection glass, or a fume or particle evacuation system.

Catalogs

No catalogs are available for this product.

See all of SIC Marking‘s catalogsRelated Searches

- Marking machine

- Laser marking workstation

- Metal marking workstation

- Benchtop marking workstation

- Plastic marking workstation

- Industrial marking workstation

- Automated marking machine

- High-speed marking machine

- Compact marking workstation

- Dot peen marking machine

- Integration marking machine

- Air-cooled marking machine

- Pneumatic marking machine

- Marking machine for the automotive industry

- Marking system

- Deep marking marking machine

- Computer-controlled marking machine

- Metal marking machine

- Tube marking machine

- Continuous marking machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.