- Products

- Catalogs

- News & Trends

- Exhibitions

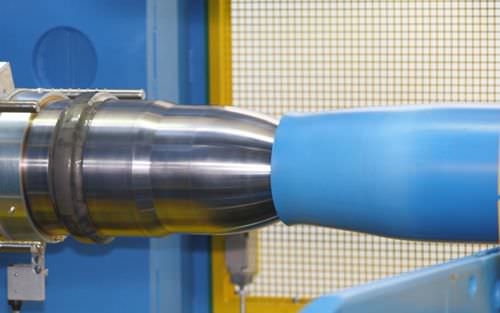

Automatic belling machine STARBELLfor PVC pipes

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Applications

- for PVC pipes

Description

The advantages and key features of this product are sica-patented forming system that has special heating process and a mechanical mandrel held process for final forming. It has two ovens - hot air and contact purposes. The combination gives a product of final heating for optimal deformability for forming sockets that are compliant with pipes resistance class. The socket is cooled with ventilated air. It also has improved production rate on an hourly basis. This bells machine also follows the same pace at the rate of automatic bioriented pipe lines.

The forming of sockets with EUR-type gasket seat and Z-joint are done. Also processing of PVC-O pipes of up to PN32 class are done. Processing of pipes of various lengths are done at the same time and upsetting flange of the socket-edge is in the forming station.

Related Searches

- Automatic sawing machine

- Band sawing machine

- Tube saw

- Plastic sawing machine

- CNC sawing machine

- PVC sawing machine

- Belling machine

- Automatic belling machine

- PVC pipe belling machine

- Extrusion line saw

- Caterpillar haul-off

- Extrusion line caterpillar haul-off

- Filler and cutting unit

- PP pipe belling machine

- Belt haul-off unit

- PE pipe belling machine

- Corrugated pipe belling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.