- Products

- Catalogs

- News & Trends

- Exhibitions

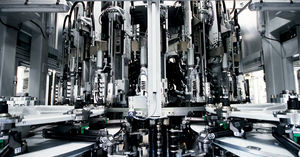

Stretch blow molding machine EvoBLOW PHfor bottlesfor the beverage industry

Add to favorites

Compare this product

Characteristics

- Type

- stretch

- Finished product

- for bottles

- Other characteristics

- for the beverage industry

Description

Our most reliable and cost-efficient solution for your industrial needs, the Sidel Matrix PH blower adds a new dimension to our preferential heating technology.

It combines the benefits of a proven PH process with a modular Matrix blower to support FHPC production. Sidel’s preferential heating process controls material distribution for ideal container shape and wall thickness:

■ Heating modules equipped with infrared (IR) lamps

■ Selective heating via series of reflecting and non-reflecting zones on reflectors positioned opposite IR lamps

■ Constant preform rotation for repeatability of differentiated heating profile

■ Reliable, mechanical angular positioning of preform from preform-loading to bottle outfeed

■ Precisely targeted temperature profile for uniform material distribution

Neck orientation

When cap orientation is needed, an in-oven indexation system is available. This is a simple method of orienting the cap according to bottle shape, product pouring and label orientation. The machine configuration and output are customised accordingly and evaluated by Sidel experts.

Catalogs

No catalogs are available for this product.

See all of SIDEL‘s catalogsRelated Searches

- Blow moulding machine

- Bottle blow moulding machine

- Blow molding machine for the food industry

- Stretch blow moulding machine

- Container blow molding machine

- PET blow moulding machine

- PET bottle blow molding machine

- Electric blow molding machine

- Blow molding machine for the beverage industry

- PET container blow molding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.