- Products

- Catalogs

- News & Trends

- Exhibitions

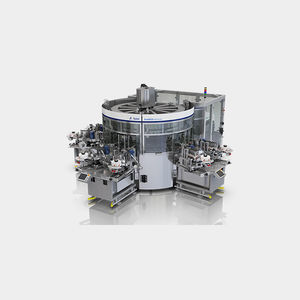

Automatic labeler EvoDECO Multifor bottlesfor the beverage industryhot-melt glue

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product application

- for bottles

- Applications

- for the beverage industry

- Type

- for self-adhesive labels, hot-melt glue, cold-glue

- Other characteristics

- rotary

- Throughput

Max.: 81,000 p/h

Min.: 6,000 p/h

Description

Sidel’s most flexible labelling solution, the EvoDECO Multi, brings modularity into labelling. It offers a standardised carousel that can be equipped with up to four different labelling technologies: roll-fed, self-adhesive, cold glue and hot melt.

The EvoDECO Multi allows for up to 36 layout configurations and a 30% faster changeover time. Switching between the various labelling modules is quick and easy, thanks to Plug & Play connections that give producers the freedom of labelling choice and total flexibility.

• Flexibility

• Modularity

• Performance

Total labelling flexibility for top brand experience

The EvoDECO Multi allows manufacturers to set up the machine for their unique labelling needs:

• Handles several types of labels (roll-fed, self-adhesive, cold glue pre-cut and hot melt wraparound paper labels)

• Varying formats and dimensions from 0.1L to 5L possible

• Manages different types of containers and packaging materials (PET, HDPE, glass)

Enhanced machine uptime

In the design of the EvoDECO Multi, special attention has been paid to ergonomics and operator safety, resulting in increased uptime:

• Up to 98% efficiency with non-stop labelling

• 30% faster changeover time

• 40% less maintenance time

• Easy operations, cleaning and maintenance are facilitated by its open, frameless structure, together with the re-designing of all the single modules

Reduced TCO

New brushless motors integrated into the carousel and the labelling stations remove the need for lubrication and achieve great energy savings:

• 40% less electrical consumption

VIDEO

Catalogs

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Bottle filler

- Palletizer

- Bottle labeling machine

- Shrink wrapper

- Automatic shrink wrapper

- Multi-head filler

- Side labelling machine

- SIDEL packaging line

- Case packer

- Robotic palletizer

- Automatic case packer

- Shrink wrapper with shrink tunnel

- Compact filler

- Labeller for the beverage industry

- Wrap-around labelling machine

- Compact labelling machine

- Can filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.