- Products

- Catalogs

- News & Trends

- Exhibitions

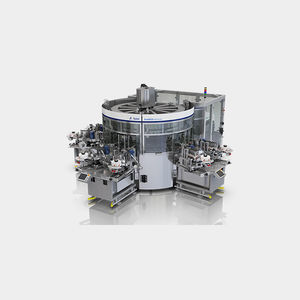

Automatic labeler EvoDECO Cold Gluefor bottlessidefor the food and beverage industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product application

- for bottles

- Label positioning

- side

- Applications

- for the food and beverage industry

- Type

- cold-glue

- Throughput

24,000 p/h, 48,000 p/h, 60,000 p/h, 81,000 p/h

Description

Sidel's EvoDECO Cold Glue labeller is available in six carousel sizes and can feature up to five labelling stations, making it easy to configure according to bottle size, output need and product type.

Capable to generate outputs of up to 81,000 containers per hour, the labelling solution handles partial pre-cut paper labels, as such it is particularly suitable for the beer, food, home and personal care markets.

Designed for top hygienic requirements

The EvoDECO Cold Glue labeller ensures utmost hygiene:

• Features a fully washable stainless-steel structure and components

• Boasts an automatic cleaning system dedicated to all the parts that come into direct contact with the glue

Consistent uptime and flexibility

The EvoDECO Cold Glue labeller maximises uptime and flexibility thanks to:

• Automatic label magazine loading system, for easier operations

• Capability to handle any output speed the user needs, from 6,000 to 81,000 bph

• Quick-release tool-less label pallets, for quick changeover time

• Equipped with brushless motorisation of the bottle platforms to smoothly handle round and shaped bottles

• A vision system can be added, for accurate bottle orientation and label positioning

Optimised resource management

The Sidel EvoDECO Cold Glue labeller includes optimised glue and resource management:

• Enhanced control with micrometric adjustments of the glue roller

• Utilises a Multiple Labyrinth seal to protect against water

• Consumes 40% less electricity

• Less glue consumption and zero lubricant required

VIDEO

Catalogs

No catalogs are available for this product.

See all of SIDEL‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Bottle filler

- Palletizer

- Bottle labeling machine

- Shrink wrapper

- Automatic sleeve wrapping machine

- Multi-head filler

- Side labelling machine

- SIDEL packaging line

- Case packer

- Robotic palletizer

- Automatic case packer

- Shrink wrapper with shrink tunnel

- Compact filler

- Labeller for the beverage industry

- Wrap-around labelling machine

- Compact labelling machine

- Can filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.