Oil/water separator filter bag QUALIPOCHE MAXfor liquidspolypropylenedouble-layer

Add to favorites

Compare this product

Characteristics

- Applications

- for liquids, for oil/water separators

- Material

- polypropylene

- Type

- welded, double-layer

Description

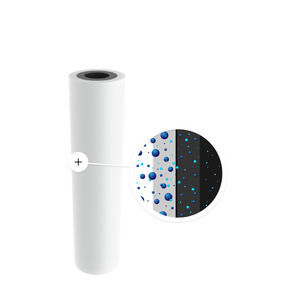

Polypropylene filtration bag with combined technologies allowing a much longer life-span compared to standard bags.

2 technologies combined

The internal part of the bag is made of a rigid PP meltblown prefilter with a thickness of 10 mm. This pre-filter with a degressive porosity has a retention capacity 4 to 10 times higher than standard filters while eliminating the traces of oil present in the liquids.

The external part of the bag is made of a polypropylene felt. This final step guarantees the porosity and the filtration efficiency of the whole.

Filtration without bypass guaranteed

The 2 parts corresponding to the pre-filter and the felt are directly welded on the molded ring of your choice. This improvement compared to equivalent products on the market allows to guarantee a filtration by stage without any by-pass.

Made from 100% polypropylene and without any seams, QUALIPOCHE™ MAX bags guarantee you a filtration without silicones and are also perfectly adapted to food applications.

Features & Benefits

Very high capacity economic bag.

Increased bag life.

Reduced number of stops and bag consumption.

Retention of hydrocarbon pollution thanks to the meltblown prefilter.

Wide range from 1 to 100 μm.

Available in size 10 and 20.

100% polypropylene.

Welded construction to avoid any risk of contamination.

FDA compliant.

Made from silicone-free materials.

Lot number on bags and carton.

Catalogs

QUALIPOCHE MAX

2 Pages

Related Searches

- Liquid separator filter

- Filter with cartridge

- Filter cartridge

- Solid classifier

- Industrial filter cartridge

- Pressure separator filter

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Liquids separator

- Filtration system

- Eddy current separator

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Filter element

- Liquid filtration system

- Gravity classifier

- Hydraulic filter

- Particle classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.