Design software Calibre® MPCpromodelingprocess controlcalibration

Add to favorites

Compare this product

Characteristics

- Function

- calibration, development, modeling, design, verification, process control, sizing

- Applications

- process, optical

Description

The Calibre Mask Process Correction family of rule and model-based products is used in advanced photomask manufacturing to correct for systematic mask lithography and process error sources to ensure that the mask critical dimension signature is within specification.

Learn how Calibre nmMPC continues to lead the way, establishing a new benchmark in accuracy and reliability. This synergistic approach to mask modeling sets a new standard in the mask industry for both mask models and MPC accuracy.

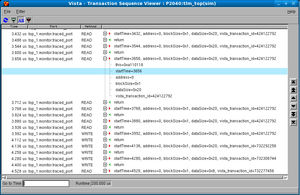

Validation for multi-beam mask lithography

Mask Process Correction (MPC) is well established as a necessary step in mask data preparation (MDP) for electron beam mask manufacturing at advanced technology nodes from 14nm and beyond. MPC typically uses an electron scatter model to represent e-beam exposure and a process model to represent develop and etch process effects. The models are used to iteratively simulate the position of layout feature edges and move edge segments to maximize the edge position accuracy of the completed mask. Selective dose assignment can be used in conjunction with edge movement to simultaneously maximize process window and edge position accuracy.

MPC methodology for model calibration and layout correction has been developed and optimized for the vector shaped beam (VSB) mask writers that represent the dominant mask lithography technology in use today for advanced mask manufacturing. Multi-beam mask writers (MBMW) have recently been introduced and are now beginning to be used in volume photomask production.

VIDEO

Catalogs

No catalogs are available for this product.

See all of SIEMENS EDA‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Windows software solution

- Control software solution

- Online software

- Real-time software solution

- Design software solution

- 3D software solution

- Interface software

- Measurement software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Development software

- Network software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.