Design software Design Flowsprototypingdevelopmentplanning

Add to favorites

Compare this product

Characteristics

- Function

- development, design, planning, verification, interoperability, prototyping

- Applications

- for packaging

- Other characteristics

- high-performance

Description

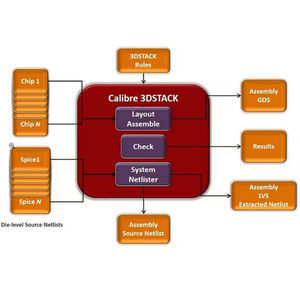

Today's high-performance products require advanced IC packaging that utilizes heterogeneous silicon (chiplets) to be integrated into multi-chip, wafer-based HDAP packages. Different vertical markets often have specific needs and corresponding design flows as shown below.

Common industry IC packaging design flows

Advanced IC packaging is critical to industries where high-performance is mandatory, such as fabless, systems, defense and aerospace, OSATs and foundries.

Systems Companies

By integrating functionality into systems-in-packages, automotive suppliers can leverage these advanced IC packages. Companies that incorporate custom ASICs and SoCs on their PCBs, such as telecom, networking switches, data center hardware, and high-performance computer peripherals, require optimized IC packages to meet performance, size, and manufacturing costs. A key component of the Xpedition HDAP flow is Xpedition Substrate Integrator where IC, package, and system PCB substrate technologies can be prototyped, integrated, and optimized using the system PCB as a reference to drive package ball-out and signal assignments to provide best-in-class physical verification and signoff.

Lower costs are also achieved by integrating functionality into systems-in-package (SiP), a fact that automotive sub-system suppliers leverage when developing mmWave technologies and products.

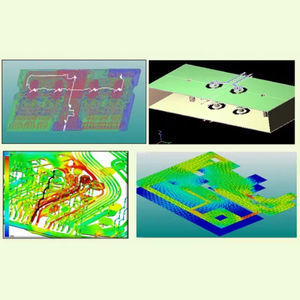

Defense & Aerospace Companies

Multi-chip modules developed in the context of their PCBs meet performance and size requirements. Commonly developed by military and aerospace companies, multi-chip modules (MCMs) and SiP developed in context of their PCBs are better equipped to meet performance and size requirements.

VIDEO

Catalogs

No catalogs are available for this product.

See all of SIEMENS EDA‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- Online software

- Design software solution

- 3D software solution

- Measurement software

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Development software

- Network software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.