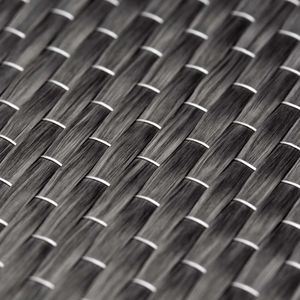

Roving technical fabric carbon fiberindustrialenvironmentally friendly

Add to favorites

Compare this product

Characteristics

- Type

- roving

- Material

- carbon fiber

- Applications

- industrial

- Other characteristics

- non-woven, environmentally friendly

Description

The SigmaRF range utilizes our own internal production waste as well as that of our customers and suppliers, to convert these discontinuous lengths of fiber (typically 50-75mm in length) into a non-woven conformable mat. Our approach is highly energy efficient and provides one of the most environmentally friendly recycled products available on the market.

SigmaRF is suitable for many applications which currently use virgin carbon fiber with thermoset or thermoplastic matrix materials, or engineered plastics or metal. SigmaRF is the solution for customers looking for a greener, more environmentally friendly composite part.

Product Attributes:

One of the greenest solution for recycled CF – no unfriendly recovery processes, such as pyrolysis or solvolysis

Cost effective for non-structural and semi-structural components.

Consistent quality with low FAW variations

Fiber retains original sizing system for improved resin compatibility and translation of properties

Excellent pre-forming behavior

Good mechanical properties – Data available on request

Suitable for pre-preg processing, RTM, Vacuum Infusion and Hand-Lay methods

Catalogs

No catalogs are available for this product.

See all of Sigmatex‘s catalogsRelated Searches

- Industrial cloth

- Carbon technical fabric

- Cloth for the automotive industry

- Carbon fiber technical fabric

- Maritime industry technical fabric

- Unidirectional technical fabric

- Non-woven technical fabric

- Technical fabric for the aerospace industry

- Environmentally friendly technical fabric

- Multiaxial technical fabric

- Roving technical fabric

- Technical fabric for the aeronautical industry

- Fiber cloth technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.