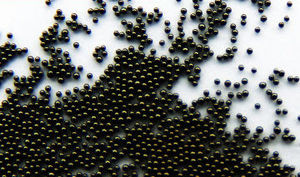

Ceramic bead grinding

Add to favorites

Compare this product

Characteristics

- Material

- ceramic

- Applications

- grinding

Description

SiLibeads® SPECIAL, made of silicon nitride (Si3N4), yttrium oxide (Y2O3), zirconium oxide / magnesium stabilized and strontium ferrite (SHF) are ceramic beads developed for your special requirements, new applications and products. Further innovative compositions such as tungsten carbide (WC and composites) and silicon carbide (SiC) are under development and will be introduced as products in the near future.

Fields of application

Ceramic beads made of Silicon nitride (Si3N4)

Beads for lowest possible product contamination, for so-called autogenous grinding / dispersion:

for dispersion and preparation under oxygen-free conditions

preparation of silicon and battery materials

sintering bed with good thermal conductivity for special products

Ceramic beads made of yttrium oxide (Y2O3)

Beads for lowest possible product contamination, for autogenous grinding / dispersion

beads for dispersing and processing high-purity yttrium or rare earth products

sintering bed for special products

Ceramic beads made of zirconium oxide / magnesium stabilized

beads for lowest possible product contamination, for autogenous grinding / dispersion

Ceramic beads made of hard magnetic strontium ferrite (SHF)

application as grinding beads in dry grinding process using an applied external magnetic field

application as a grinding beads in the wet grinding process using an applied external magnetic field

magnetic microspheres for water treatment or as magnetic carrier material in medicine

Quality attributes

suitable for autogenous grinding

for product-specific and new applications

high-purity raw materials

dense structure

high stability

VIDEO

Catalogs

No catalogs are available for this product.

See all of SIGMUND LINDNER‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.