- Metrology - Laboratory

- Inspection and Monitoring

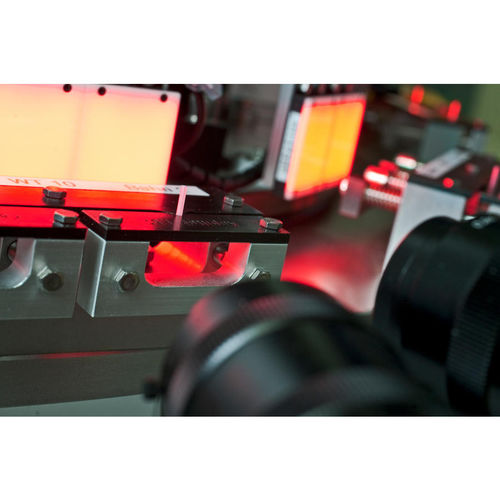

- Optical inspection system

- SIM Automation GmbH

Camera inspection system SIM Visionultrasonicopticalautomated

Add to favorites

Compare this product

Characteristics

- Technology

- camera, ultrasonic, optical

- Operational mode

- automated

- Type

- quality control, measurement

- Applications

- for the pharmaceutical industry, for the automotive industry, for non-destructive testing

Description

Inspection technology – Measuring systems and testing plants – Important in all branches

Inspection technology has a special role, is important in all branches, is complex and is absolutely essential for quality control and safeguarding the process. Each product has individual test values and criteria. The technological requirements here are high. SIM Automation GmbH provides customer-specific measuring and testing plants in line with our SIM concept.

Our portfolio ranges from single measuring systems with manual assembly all the way through to fully integrated and fully automated testing plants using robots. The sky is the limit when it comes to inspections. Whether optical, acoustic or electrical systems with and without parts contact or state-of-the-art data preparation and analysis, SIM Automation GmbH offers complete solutions from a single source.

Measuring and testing systems we have been involved in:

•Camera systems with corresponding image processing:

•Part recognition, positioning, color and surface examination, checking for damages

•Optical / tactile / ultrasonic tests using sensors and displacement measurement systems

•Leakage and pressure tests

•Inspection and monitoring of filling level

•Run-out properties and accuracy

•Backlash measurement

•Electrical tests and measurements:

•Electrical values, check measurements, switching and opening properties

Catalogs

No catalogs are available for this product.

See all of SIM Automation GmbH‘s catalogsRelated Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Quality inspection system

- Measurement inspection system

- Optical inspection system

- Ultrasonic inspection system

- Quality control inspection system

- Inspection system for the automotive industry

- Inspection system for the pharmaceutical industry

- NDT inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.