- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

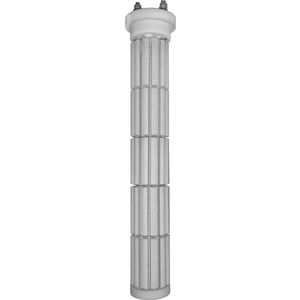

AC infrared heater FSR for heatingprocessstainless steel

Add to favorites

Compare this product

Characteristics

- Power source

- AC

- Applications

- for heating, process

- Other characteristics

- stainless steel

- Power

Min.: 50 W

(0.07 hp)Max.: 1,200 W

(1.63 hp)

Description

Ceramic infrared radiators are made of highly flameproof ceramics with ceramic enamel coatings and heating coils from resistance wire inside. Infrared radiators use the electromagnetic radiation phenomena to transfer heat to the objects with lower temperatures. Depending on the heater power, the electromagnetic wave of the heater ranges from 2 μm to 10 μm length.

FSR panel heaters can be used universally and are suitable for building up heating systems with any geometry. FSR are ceramic infrared emitters that are designed for operating temperatures of up to 750°C. Optionally, area outputs of up to 64 kW/m² can be installed. They are manufactured using a full ceramic casting process and are characterized by their concave design. Due to this design, there is a gap between the radiator and the mounting plate, which reduces the heat absorption of the wiring space. They are available in three standard designs and cover the power range from 60 W to 1000 W.

HTS high temperature heaters are ceramic infrared panel heaters, which can be used for operating temperatures up to 860°C and surface ratings up to 64 kW/m². HTS heaters are produced using a hollow-casting ceramic process and are filled with thermal insulation material. This improves the radiant power output to the material to be heated. Furthermore, there is a significant reduction in heat dissipated in the wiring space, so that additional insulation of the heating area is usually not required. Compared with IR heaters, which are produced by using full-poured casting processes, HTS heaters have a considerably reduced heating-up time and, depending on the type of application, enable energy savings of up to 25 %.

Catalogs

No catalogs are available for this product.

See all of SIMEX Sp. z o.o.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.