- Products

- Vacuum bag

- Simtech

- Products

- Catalogs

- News & Trends

- Exhibitions

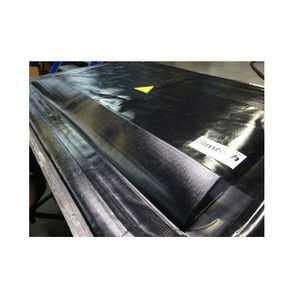

Automobile vacuum bag FBRfor glassfor laminatingmilitary

Add to favorites

Compare this product

Characteristics

- Product applications

- for automobiles, for glass, for laminating, military

Description

The FBR reusable vacuum bag is a high resistance temperature rubber bag intended for glass laminating. This laminating vacuum bag is used to assemble the glass during the pre-lamination process in automatic oven. The glass sheets are inserted inside the bag. Consolidation takes place under the action of heat and de-airing. The laminating vacuum bag closes with a flap closure system on the oven frame.

User / use

Automobile industry: Complete EVA cycle, PVB pre-lamination, lamination of specific glass parts

Architectural industry: Glass partitions, safety partitions, glass with acoustic properties, anti-UV glazing, heating glass

Military industry: Bullet-proof laminated glass

Research and development: Lamination of glass specimens

General industry: LCD screens, solar panels

Technical characteristics

Reusable glass vacuum bags come in the form of an envelope, and its flap closing system ensures perfect sealing. The vacuum channel developed and patented by Simtech ensures efficient deairing. Accessories used for holding on the oven carrier frame are assembled by vulcanisation, which gives them high strength and longer service life.

Performance

The FBR vacuum bag is suitable for continuous production and can withstand temperatures of up to 135°C. Several types of glass can be laminated in a single vacuum bag, which allows you to control your production costs. The FBR vacuum pouch is composed of an internal embossed non-stick coating to reduce any internal pollution from PVB residues and to ensure homogeneous diffusion of the heat. The vacuum bag requires very little maintenance.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.