- Products

- Vacuum bag

- Simtech

- Products

- Catalogs

- News & Trends

- Exhibitions

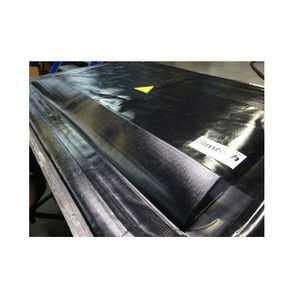

Vacuum bag for high-temperature applications OBRfor automobilesfor panelsmilitary

Add to favorites

Compare this product

Characteristics

- Product applications

- for high-temperature applications, for automobiles, for panels, military, for industrial applications, for industrial applications, for glass

Description

The reusable OBR type elastomeric vacuum bag comes in the form of a flexible envelope equipped with a simple, fast and airtight closure system as well as a vacuum exhaust system over its entire internal surface. It enables deairing of complexes and withstands high temperatures in the furnace or oven. Many users around the world are satisfied with this tool.

User / use

Automotive industry: laminating of side windows, PVB specific windshield, sunroof, acoustic glass.

Architectural industry: for creation of glass steps, safety railings, acoustic glass, anti-UV glass, balustrades.

Military industry: bullet-proof laminated glass.

Composite industry: compacting and crosslinking of pre-impregnated composite plies.

General industry: LCD screen, photovoltaic panels, vacuum bonding.

Technical characteristics

The OBR vacuum bags and accessories are vulcanised in bulk (automobile tire manufacturing process), which gives them very high strength and excellent flexibility.

They are closed and sealed by a rubber gasket with a clip or fold.

The anti-stick internal exhaust coating can be cleaned by simply wiping with a wiper. This neutral coating does not adhere to any interlayer. This non-polluting concept avoids production residue and repeated cleaning.

Performance

OBR vacuum bags can be used in manual laminating processes that are flat, with significant curvatures, contain perforations, added elements, of varying sizes/thicknesses, of irregular shape as well as multi-layer complexes.

The maximum temperature of use for this model of bag is 140°C / 285°F.

The bags are designed to withstand an optimal vacuum of -0.99 mbar.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.