- Products

- Vacuum bag

- Simtech

- Products

- Catalogs

- News & Trends

- Exhibitions

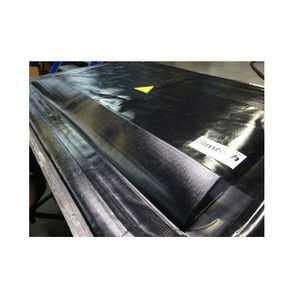

Vacuum bag for high-temperature applications ABSJ/OBSJfor autoclavesfurnacemilitary

Add to favorites

Compare this product

Characteristics

- Product applications

- for high-temperature applications, for autoclaves, furnace, military, for glass

Description

Laminating vacuum bag for high temperature comes in the form of a flexible envelope equipped with a simple, fast and airtight closure system as well as a vacuum exhaust system over its entire internal surface. It is reusable. It allows for optimal application of vacuum and withstands high temperatures in the oven or Autoclave.

User / use

Architectural industry: for creation of glass steps, safety railings, acoustic glass, anti-UV glass, balustrades.

Military industry: bullet-proof laminated glass.

Composite industry: compacting and crosslinking of pre-impregnated composite plies.

General industry: LCD screen, photovoltaic panels, vacuum bonding.

Technical characteristics

The Laminating vacuum bag for high temperature and accessories are vulcanised in bulk (automobile tire manufacturing process), which gives them very high strength and excellent flexibility.

They are closed and sealed by a rubber gasket with a clip.

The anti-stick internal coating can be cleaned. This neutral coating does not adhere to any interlayer and pollution, avoiding production residue and repeated cleaning.

Performance and benefits

OBSJ/ABSJ vacuum bags can be used in manual laminating processes that are flat, with significant curvatures, contain perforations, added elements, of varying sizes/thicknesses, of irregular shape as well as multi-layer complexes.

The maximum temperature of use for this model of bag is 200°C / 392°F.

The bags are designed to withstand an optimal vacuum of -0.99 mbar.

The quick and simple closure system makes it possible to limit handling time and to avoid scratching the glass.

They can be used horizontally on a trolley or table.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.