Analysis software fe-safe/Rubberinterfacedevelopmentsimulation

Add to favorites

Compare this product

Characteristics

- Function

- analysis, interface, development, simulation, design, database

- Applications

- industrial

Description

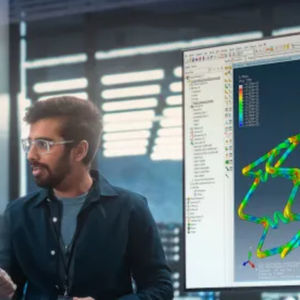

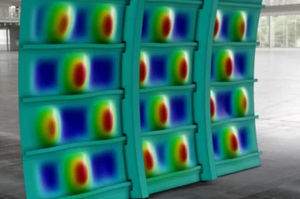

Introducing the first commercially available software tool for the fatigue analysis of rubber and elastomers. Developers of rubber materials, components and systems increasingly rely on simulation as a routine means to address design issues. The need for durability simulation is growing exponentially and durability often dominates development agendas. Fatigue analysis solutions from Finite Element Analysis (FEA) have been commercially available for metallic components for many years. These solutions have played a vital role in qualifying design concepts across various industrial sectors. Finally, there is a solution available for elastomers.

fe-safe/Rubber is a:

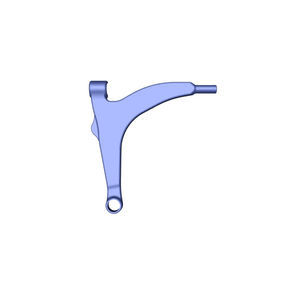

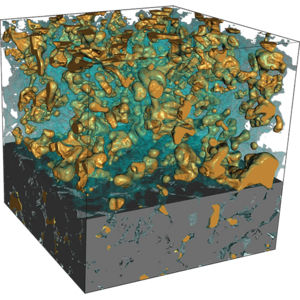

Unique, patented solution for the simulation of fatigue failure in elastomers.

Purpose-developed tool for elastomers, possessing a formidable validation.

Developed by Endurica, leaders in the development of elastomer technology.

Key Facts

Integrated into fe-safe’s friendly user-interface to access finite element results, define duty cycles and specify materials.

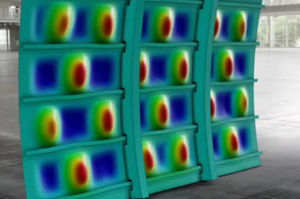

Accurate Material Models - highly nonlinear stress strain curves, Mullin's effect, strain crystallization.

Temperature Dependence

Time Dependence

Contains a fatigue characterization scheme for efficiency and ease of application in fe-safe/Rubber. It uses material properties that are accessible through readily available experiments.

Pre-populated Materials Database and add proprietary materials to your own database.

Critical Plane analysis for multiaxial loading:

A patented critical plane algorithm that considers the individual loading experiences on each potential failure plane of the material.

Catalogs

No catalogs are available for this product.

See all of SIMULIA‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- SIMULIA analysis software

- SIMULIA process software

- Control software solution

- SIMULIA CAD software

- Real-time software solution

- Online software

- SIMULIA design software

- SIMULIA 3D software

- SIMULIA interface software

- Measurement software

- SIMULIA industrial software

- SIMULIA quality software

- SIMULIA simulation software

- Visualization software solution

- Automated software

- SIMULIA development software

- Network software solution

- Machine software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.