Calculation software Verity™testanalysisengineering

Add to favorites

Compare this product

Characteristics

- Function

- analysis, engineering, test, calculation

- Other characteristics

- master

Description

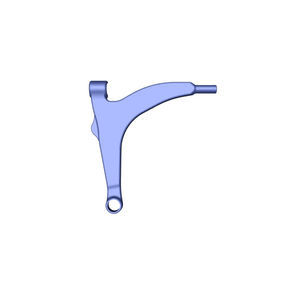

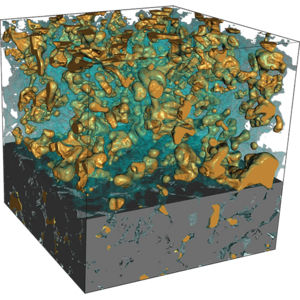

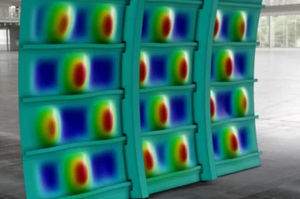

The calculation of fatigue lives has traditionally been a notoriously complex and difficult task. The prediction of fatigue life and failure locations for welded joints and welded structures, including spot welds, can often result in poor correlation with test data. The Verity Structural Stress Method was developed and patented by Battelle. It was a major breakthrough in the fatigue analysis of welded joints from finite element models.

Verity in fe-safe combines Verity for the fatigue of welded structures with the advanced features of fe-safe for fatigue analysis for finite element models. It allows companies to reduce or avoid the expense of testing to validate the integrity of designs and avoid the common practice of over-engineering due to the uncertainty of fatigue life.

Verity in fe-safe at a Glance

Removes the subjective decisions by the user, thereby increasing reliability and accuracy.

Works from nodal forces at the weld lines, allowing coarse meshes to be used.

Uses a single master S-N curve for all welds and for all thicknesses of sheet and plate.

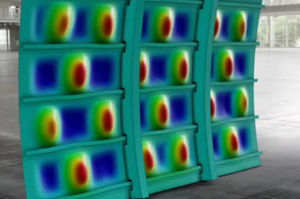

Offers consistent structural stress calculations regardless of mesh density or element types.

Achieves new levels of accuracy and reliability.

Applicable to all types of welds, including spot welds, and all types of loading, including random vibration and sine sweep loading.

It is easy to use and automate.

Analyzes welded joints, spot welds and non-welded areas in a single run.

Validated by Battelle's Joint Industry Project using more than 3500 physical fatigue tests.

The Verity Module in fe-safe is an add-on module to fe-safe.

Catalogs

No catalogs are available for this product.

See all of SIMULIA‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- SIMULIA analysis software

- SIMULIA process software

- SIMULIA CAD software

- Control software solution

- Online software

- Real-time software solution

- SIMULIA design software

- SIMULIA 3D software

- Measurement software

- SIMULIA interface software

- SIMULIA industrial software

- SIMULIA quality software

- SIMULIA simulation software

- Visualization software solution

- Automated software

- SIMULIA development software

- Network software solution

- Machine software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.