- Packing - Handling - Logistics

- Conveying

- Vibrating feeder

- Sinex Industrie SAS

- Products

- Catalogs

- News & Trends

- Exhibitions

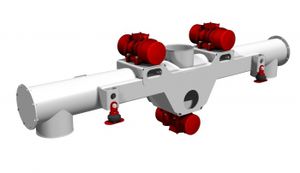

Vibrating feeder continuousbulk

Add to favorites

Compare this product

Characteristics

- Type

- vibrating

- Operating mode

- continuous

- Product applications

- bulk

Description

The Sinex vibrating feeders are used to draw out bulk materials or powders from silos from hoppers.

The capacity depends on the product nature, its density and its size. They are particularly advantageous in different dosing functions, such as: feeding of big-bags, weighers, conveyor belts, crushers, etc... They can be used in load preparation, or in continuous feeding.

These feeders troughs can be double-walled which can be cooled or heated by the mean of water circulation device, and then they can be used to feed kilns. The trough can be enlarged and then it allows a distribution of product on a large width for sprinkling, pre-drying, etc....

Efficiency: the assembly inclination from 0 to 12° can improve equipment efficiency.

Options: equipment hanged up or set on the floor, with opened or closed (dustproof covering) trough, with or without wearing coating, in HR steel or special material (synthetic rubber, Ipalen....)

Advantages: regular capacity quantity that can be adjustable continuously by potentiometer.

Low power consumption, no moving parts, so, no maintenance. Capacity can be set or automatically controlled by the mean of a SINEX electronic regulation or by analog setpoint 4-20 mA or 0-10 V depending on various parameters. Possibility to fit amplitude sensors.

Related Searches

- Rail conveyor

- Transporting conveyor

- Feeder

- Vibration motor

- Automated feeder

- Vibrating feeder

- Pneumatic vibrator

- Bulk feeder

- Rotary vibration motor

- Logistic conveyor

- Trough conveyor

- Air conveyor

- Dosing feeder

- Continuous feeder

- Vibrating conveyor

- Motorized feeder

- Cooling conveyor

- Mechanical feeder

- Volumetric dosing feeder

- Powder feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.