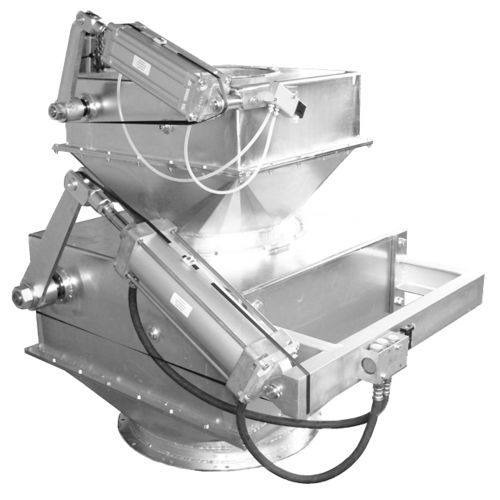

Two flap shutters mounted one on top of the other form a Double-Flap Sluice.

The applications for Double-Flap Sluices are as follows:

• When bulk materials are conveyed to another pressure level, such as the discharge from cyclones

• When products or bulk materials are progressively cycled back and forth, such as with cement and glass production

• If products or bulk materials in other processes or systems are progressively conveyed, such as in the entry or discharge in incineration or biogas plants

Special features of the flaps are:

• The sophisticated mechanism, no friction and shear forces occur on the seal, so that it does not wear

• The closing flap swings completely from the product stream. The flowing product is therefore not damaged or modified

• No wear of the flap develops dues to the flap swinging completely from the product flow

Contrary to the Cellular Wheel Sluice, the Double-Flap Sluice has no difficulty with high temperatures, big grain sizes, large flow capacities and high difference pressures. It cannot block up, has almost no wear and tear and the foreign air due to clearance losses can be disregarded.

The Double-Flap Sluice is in particular suited for such cases where the charging is made into a higher pressure, since the difference pressure is pressing the flap against the outlet. Shall, however, the charging be made into a lower pressure, the lever system and the drive must be reinforced in case of higher pressure differences.