- Production Machines

- Plastics Processing

- Hot-runner plastic injection mold

- Sino Mould Co.,Ltd Huangyan Taizhou

- Products

- Catalogs

- News & Trends

- Exhibitions

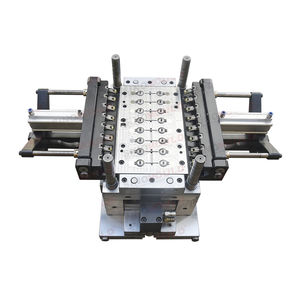

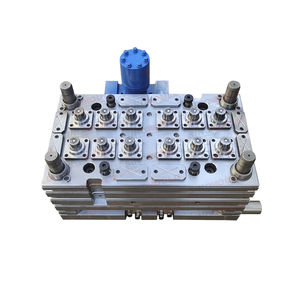

Multi-cavity plastic injection mold hot-runnerpreformsmall series

Add to favorites

Compare this product

Characteristics

- Type of mold

- multi-cavity, hot-runner

- Cast parts

- preform

- Operation

- small series, medium series

- Applications

- for the packaging industry

- Certifications

- ISO 9001

Description

Sino Mould offers superior PET preform injection molding solutions for various application and volume, such as mineral water, C.S.D., fruit juice, milk, milk-based drinks, tea, functional beverages, etc. So we can see that PET bottles are a huge market in the global. The popular method of making PET bottles is the two-step process: first step - PET is injection molded into a preform (like a tube with screw); second step - the preforms will be reheated, stretched and blown into its final shape.

1. About PET material

Polyethylene terephthalate (uses of PET), is the most common thermoplastic polymer resin used in containers for liquids and foods, as the following features:

- Security

- Excellent in gas and fair moisture barrier

- Lightweight

- Strong and impact-resistant

2. Preform injection molding system

There is always a complete PET preform injection molding system for making preforms, in addition to preform injection moulding machine and PET Preform Injection Mould, further comprising: dryer for large amount PET, dehumidifying dryer, chiller, cooling tower, auto loader, preform out robot, conveyor and air dehumidifier for well preform molding environment… The complete system could be simple and complex, which depends on how the production capacity required and budget invested by customers.

3. PET preform molding technical operators

More about the tricks for efficient PET preform injection molding solutions, welcome to contact us now! Sino Mould would be glad to provide the proposal for highest productivity levels and the lowest production costs.

VIDEO

Other Sino Mould Co.,Ltd Huangyan Taizhou products

Package Mould

Related Searches

- Plastic injection mold

- Multi-cavity plastic injection mold

- Plastic injection mold for the packaging industry

- Hot-runner plastic injection mold

- ISO 9001 plastic injection mold

- Small series plastic injection mold

- Large series plastic injection mold

- Medium series plastic injection mold

- Packaging plastic injection mold

- Technical parts plastic injection mold

- Plastic injection mold for industrial applications

- Plastic injection mold for the automotive industry

- Aesthetic parts plastic injection mold

- Crate plastic injection mold

- IML plastic injection mold

- Preform plastic injection mold

- Covers plastic injection mold

- Plastic injection mold for the food industry

- Chair plastic injection mold

- Plastic injection mold for the furniture industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.