- Production Machines

- Plastics Processing

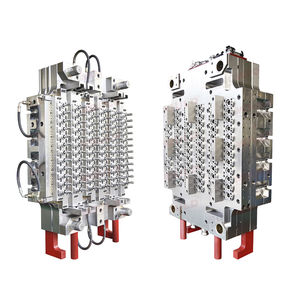

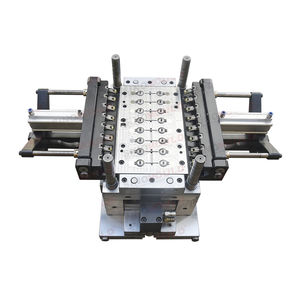

- Hot-runner plastic injection mold

- Sino Mould Co.,Ltd Huangyan Taizhou

- Products

- Catalogs

- News & Trends

- Exhibitions

Multi-cavity plastic injection mold hot-runnerpackagingsmall series

Add to favorites

Compare this product

Characteristics

- Type of mold

- multi-cavity, hot-runner

- Cast parts

- packaging

- Operation

- small series, medium series

- Applications

- for the packaging industry

- Certifications

- ISO 9001

Description

Five Highlights of SINOPK Plastic Cap Mould Order Process

1. Make customers more easy for purchasing: just tell us what you want regarding the cap or the cap mould, then expert SINOPK team would provide the best solution. So customers could do their other work important well.

2. Faster delivery time: SINOPK could reduce the lead time much as the rigorous QC system and standard mould components prepared in advance.

3. Regular mould process report: to help customers know well about their orders and arrange the related plans, SINOPK team would offer the mould process report per week at least.

4. Quick Service Response: as the complete mould process, every drawing and data would be recorded well, so no matter for question or repeat mould tooling, our team could make it fast to find the final mould data.

5. Get some ready caps as sample for final customers as the mould testing in SINOPK workshop: some customers would prefer to pay for the material cost to get the good plastic caps delivered together with moulds, so before they make the cap moulds run on the machines, they have ready caps for business display to develop the market quickly.

Get the Satisfying Plastic Cap Mould from SINOPK Now!

Looking for high quality Plastic Cap Mould with excellent service? Leave your message here to tell us your idea or requirement, one of our professional engineers would give quick back to you. It would be a start of a long relationship between us.

Other Sino Mould Co.,Ltd Huangyan Taizhou products

Package Mould

Related Searches

- Plastic injection mold

- Multi-cavity plastic injection mold

- Plastic injection mold for the packaging industry

- Hot-runner plastic injection mold

- ISO 9001 plastic injection mold

- Small series plastic injection mold

- Large series plastic injection mold

- Medium series plastic injection mold

- Packaging plastic injection mold

- Technical parts plastic injection mold

- Plastic injection mold for industrial applications

- Plastic injection mold for the automotive industry

- Aesthetic parts plastic injection mold

- Crate plastic injection mold

- IML plastic injection mold

- Preform plastic injection mold

- Covers plastic injection mold

- Plastic injection mold for the food industry

- Chair plastic injection mold

- Plastic injection mold for the furniture industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.