- Production Machines

- Plastics Processing

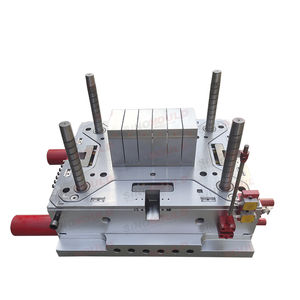

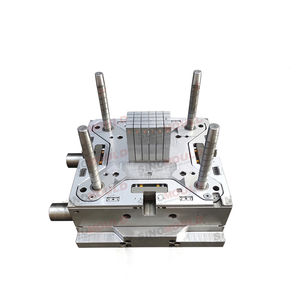

- Hot-runner plastic injection mold

- Sino Mould Co.,Ltd Huangyan Taizhou

- Products

- Catalogs

- News & Trends

- Exhibitions

Hot-runner plastic injection mold technical partslarge seriessmall series

Add to favorites

Compare this product

Characteristics

- Type of mold

- hot-runner

- Cast parts

- technical parts

- Operation

- large series, small series, medium series

- Applications

- for industrial applications, for the automotive industry

- Certifications

- ISO 9001

Description

Sino Mould production range include automotive battery series N40, N50, N70, N100, N120, N150, and N200; UPS battery series like 55AH, 90AH, 100AH; Invertor battery series like IT 500; DIN battery series like DIN55, DIN66; And any other types of plastic battery case mould making according to customer requirement.

Mould Technical Points:

1.Designed with 7tips hot runner system for balance injection, gate diameter choose according to mold flow analysis - the side two tips and middle five tips with different diameter.

2.Precision tooling to realize accuracy dimension control.

3.Use higher hardness steel for the 6 pcs core inserts to avoid any bending or core shifting.

4.Mature assembling team work for completing whole set mould.

For the battery case and cover fitting, usually we use plastic welding to realize the two parts perfect sealing, then use acid filling machine to put liquid into the battery, so the filling holes in the cover is with same shape in one line. The smooth air venting ways is very important to make the battery working long time safety. SINO pays much attention on the product design improving to get high performance battery case with standard weight.

With Dakumar Machinery for battery case injection molding machine manufacturing, we could supply complete solution for plastic battery case production line. We have supplied such turnkey solutions for our customers from Egypt, Algeria, Bulgaria, Slovenia and so on. Our engineers are going to visit customer factories for service: assemble machines, run whole production line and do technical training for staffs.

Welcome to contact us for more information.

Other Sino Mould Co.,Ltd Huangyan Taizhou products

Battery Box Mould

Related Searches

- Plastic injection mold

- Multi-cavity plastic injection mold

- Plastic injection mold for the packaging industry

- Hot-runner plastic injection mold

- ISO 9001 plastic injection mold

- Small series plastic injection mold

- Large series plastic injection mold

- Medium series plastic injection mold

- Packaging plastic injection mold

- Technical parts plastic injection mold

- Plastic injection mold for industrial applications

- Plastic injection mold for the automotive industry

- Aesthetic parts plastic injection mold

- Crate plastic injection mold

- IML plastic injection mold

- Preform plastic injection mold

- Covers plastic injection mold

- Plastic injection mold for the food industry

- Chair plastic injection mold

- Plastic injection mold for the furniture industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.