- Environment - Health - Safety

- Waste Treatment

- Vertical baling press

- SINOSPECT INDUSTRIAL CO.,LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

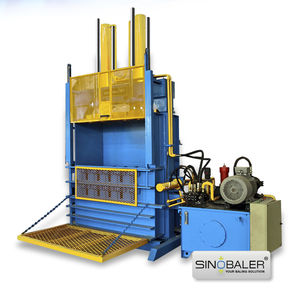

Vertical baling press SVB2-MD-400Afront-loadingfor drumsautomatic

Add to favorites

Compare this product

Characteristics

- Orientation

- vertical

- Loading

- front-loading

- Applications

- for drums

- Other characteristics

- automatic

Description

Compared to traditional drum crusher, this automatic drum crusher set does not need any manual operation for loading drums into the compression chamber or taking out the crushed métal dise from the compression chamber. The entire operation cycle including drum feeding, crushing, ram returning and metal-disc ejecting is fully automatic once the feed conveyor is started and scrap drum is placed on the conveyor. This automatic drum crusher set is composed by a rolling conveyor, a drum crushing unit and a hydraulic-driven ejecting mechanism. The conveyor and the crushing unit are interlocked electrically, that is, the conveyor will automatically stop or start again according to certain action of the crushing unit.

This Automatic crushing System can crush almost ail types of métal

drums & barrels of up to 220Litre (58 gallon) volume. Customization on the chamber size of the crushing unit can also be done by us in the case that your drum size does not fit our standard compression chamber size. With the installation of infrared ray sensor, the operation safety of this machine is well ensured because the crushing process will immediately stopped if the infrared ray detects that anything approaches to the compression chamber.

For some plants or yards that generate large quantity of scrap métal drums every day, this automatic crushing System is an optimal solution to efficiently reduce the size of the drums and subsequently saves storage room and transportation cost. Especially in some areas where labor cost is very expensive, this System can help much save labor cost on crushing the drums.

Other SINOSPECT INDUSTRIAL CO.,LTD products

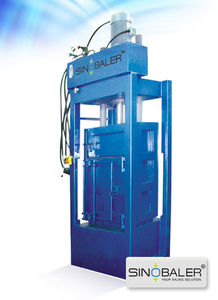

Vertical Baler / Vertical Baling Press Machine

Related Searches

- Baling press

- Vertical chamber baling press

- Cardboard baling press

- Top-loading baling press

- Horizontal baling press

- Front-loading baling press

- Trash compactor

- Automatic baling press

- Paper baling press

- Plastic baling press

- Compact baling press

- Stationary trash compactor

- Channel baling press

- Briquetting presse

- Single-chamber baling press

- Textile baling press

- Bottle baling press

- Automatic briquetting machine

- Hydraulic briquetting machine

- Hydraulic waste compactor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.