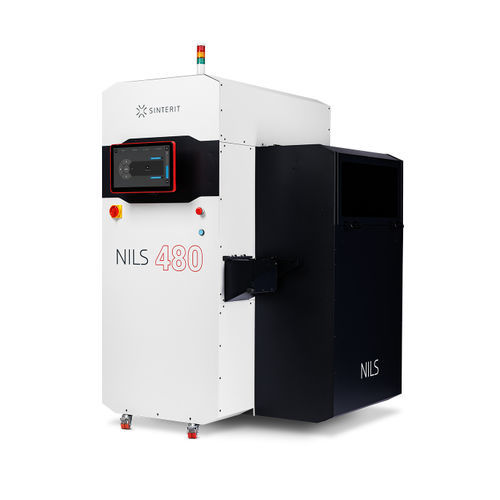

SLS 3D printer NILS 480PAPPindustrial

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- PA, PP

- Technology

- SLS

- Applications

- industrial

- X travel

200 mm

(7.87 in)- Y travel

200 mm

(7.87 in)- Z travel

330 mm

(12.99 in)- Layer thickness

Max.: 175 µm

Min.: 75 µm

- Weight

300 kg

(661.39 lb)

Description

An industrial SLS 3D printer ensuring more automated work and the best ROI on the SLS technology market.

With the reinvented productivity in the NILS 480 you can print much more, continously.

Key advantages of the NILS 480

Innovative automated systems

With its Continous Printing and Automatic Powder Dispensing Systems, you can do the same work much more efficiently. If you print a lot, these features really matter.

Industrial printing speed

The NILS 480 is equipped with the Galvo laser scanning system. This means most printing jobs can be finished within 24 hours.

Industrial build size

The NILS 480 meets the industrial market standard for size, enabling you to print much more at lower prices per part.

Best ROI on the SLS market

With the speed, build size and automated work the NILS brings, you achieve superior ROI in an industrial SLS printer – in as little as 40 days.

Continuous Printing System

With this solution, fill the powder once and print two full beds or a few lower print beds. All of this without repeating the print preparation process and powder filling. How does the NILS do this? The previous bed automatically ejects, lifting a full cake to the cooling box. The printing bed comes back and another print automatically begins.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Sinterit‘s catalogsRelated Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- Large-format 3D printing machine

- Table-top 3D printer

- TPU 3D printing machine

- Polyamide 3D printer

- 3D printing powder

- Laser sintering 3D printer

- PP 3D printer

- Plastic 3D printing powder

- Industrial 3D printing powder

- SLS 3D printing powder

- TPE 3D printer

- Prototyping 3D printing powder

- Medical 3D printing powder

- 3D printing powder for the automotive industry

- Nylon PA12

- Heat-resistant 3D printing powder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.