- Products

- Catalogs

- News & Trends

- Exhibitions

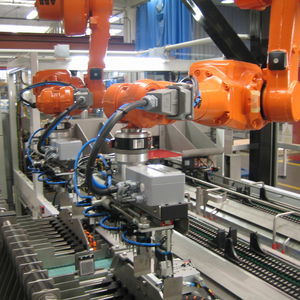

Cardboard box palletizer roboticfor boxesfor the packaging industry

Add to favorites

Compare this product

Characteristics

- Type

- robotic

- Product applications

- for boxes, for cardboard boxes

- Sector

- for the packaging industry

- Other characteristics

- automatic

Description

The anthropomorphic robots for palletising applications pose an excellent solution for all kind of stacking patterns. Thanks to their flexibility, it is possible to use these equipments serving several concurrent lines with different patterns and products. The products can be identified and palletised in different stations through innovative technical solutions.

The design and materials of the grippers are very important because, by decreasing the mechanical resistance, the number of cycles of the robotised arm can be optimized, including the positioning of empty pallets or the placement of interlayers for the stabilisation of the load.

VIDEO

Related Searches

- Palletizer

- Automatic palletizer

- Case packer

- Layer palletizer

- Robotic palletizer

- Automatic case packer

- Case palletizer

- Sack palletizer

- Cardboard box palletizer

- Depalletizer

- Palletizer for the packaging industry

- Vertical case packer

- Automatic depalletizer

- Handling palletizer

- Bottle depalletizer

- Low level infeed palletizer

- Bottle palletizer

- Package palletizer

- Adhesive tape case packer

- Robotic depalletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.