- Power Transmission - Mechanical components

- Actuator and Positioning System

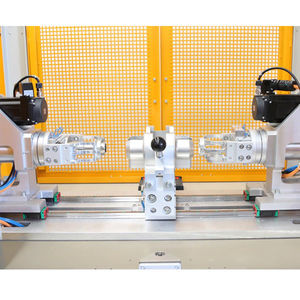

- Linear actuator

- SIRIUS ELECTRIC S.R.L.

Linear actuator MINI RFpneumaticball screwwith brushless DC motor

Add to favorites

Compare this product

Characteristics

- Movement

- linear

- Type

- pneumatic

- Technology

- ball screw

- Motor

- with brushless DC motor

- Voltage

- 230 V

- Applications

- for welding applications

- Other characteristics

- compact, low-profile, clean design

- Torque

1.3 Nm

(0.959 ft.lb)- Motor power

400 W

(0.54 hp)

Description

In the context of industrial automation aimed at the market of assembly machinery, Sirius Electric, has studied and built a new pneumatic actuator for spin welders.With this technology, most thermoplastic materials having a round shape can be welded.In the spin welding technology, the heat needed to melt the parts is produced by a circular movement combined with thrust pressure. A part to weld is held in the fixturing, while the other part is put in motion by the rotary spindle. The assembly process is easy and based on easily understood, well-known principles of physics.This actuator, very contained in size, is suitable for welding small size pieces, where the use of conventional systems is inconvenient because of size and elevated costs. The brushless motor that drives the rotary spindle is highly efficient.The new electronic drive devices on these motors, combined with our welding cycle control microprocessor, are perfectly integrated, further reducing the space needed for the wiring system

Supply voltage 230 V – 50 Hz

Absorption 0.9 kVA

Motor revolutions 6000 g/min max

Head descent cylinder 32 mm dia.

Stroke 50 mm max.

Overall dimensions 330x80x145 mm

Catalogs

No catalogs are available for this product.

See all of SIRIUS ELECTRIC S.R.L.‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Actuator

- Linear actuator

- Electric actuator

- Compact actuator

- Screw actuator

- DC actuator

- Precision actuator

- Pneumatic actuator

- Screw spindle actuator

- AC actuator

- Slide actuator

- Cylinder actuator

- 230 V actuator

- Flat actuator

- Low-profile actuator

- Actuator for welding applications

- Ultrasonic welding machine actuator

- Clean design actuator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.