- Industrial machines and equipment

- Welding and Assembly

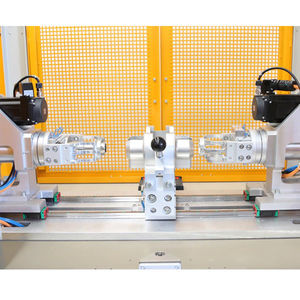

- Friction welding machine

- SIRIUS ELECTRIC S.R.L.

Friction welding machine SWP-06semi-automaticbenchtoponline

Add to favorites

Compare this product

Characteristics

- Technique

- friction

- Operational mode

- semi-automatic

- Configuration

- benchtop, online, for integration

- Applications

- for plastics

- Power supply

- 230V single phase

- Other characteristics

- programmable, rotary, with touch screen, circular

Description

The SWP 06 spin welder was designed and manufactured using state-of-the-art technologies (3D CAD, CNC). With this technology, most thermoplastic materials having a round shape can be welded.

For spin welding technology, the heat needed to melt the parts is produced by a rotating motion combined with thrust pressure. One of the parts to be welded is held by a fixture, while the other one is set in motion by a rotating spindle. The assembly process is easy and based on easily understood, well-known principles of physics. Welding joints are simple and permit a high degree of design freedom. The tools that hold the pieces to be welded are also simple and can be made by the client. The mechanical and electric solutions available create optimal working conditions with ample adjustment possibilities, making the welder ideal for most welding applications.

The welder has a highly robust structure. The motor that drives the rotating spindle is the brushless type. The motion of the motor holder head is achieved with a pneumatic system run by a proportional valve and on high-precision prismatic guides.

One of the most important features of this welder is the cycle control system managed by MICROPROCESSOR with TOUCH SCREEN.

The microprocessor can store 20 welding programmes.

uipped also with a TOUCH SCREEN microprocessor that controls the welding cycle.

Programming is easy and intuitive, with the option of setting up personalized menus and changing the language.

VIDEO

Catalogs

SPIN WELDER SWP 06

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Welding system

- Automatic welding system

- Precision welding system

- Plastic welding system

- Manual welding system

- Standalone welding system

- Compact welding system

- CNC welding system

- Welding generator

- Pneumatic welding system

- Ultrasonic welding system

- Semi-automatic welding system

- Electric welding system

- Integrated welding system

- Benchtop welding system

- High-precision welding system

- 230V single phase welding system

- CE welding system

- Programmable welding system

- 380V three-phase welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.