- Metrology - Laboratory

- Analytical Instrumentation

- Monitoring analyzer

- SITA Messtechnik

Monitoring analyzer FluoScan 3Dlaboratoryfluorescencefor integration

Add to favorites

Compare this product

Characteristics

- Application domain

- monitoring, laboratory

- Measured value

- fluorescence

- Configuration

- for integration

- Mode of use

- automatic

Description

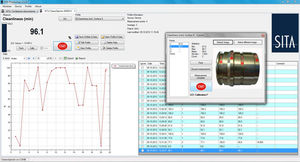

Automated cleanliness inspection with proven fluorescence sensor technology

AUTOMATED

Cleanliness inspection of three-dimensional parts' surfaces

QUICK

Surface scan of different parts detecting residual organic contamination within a very short time

RELIABLE

Robust Sensor

Reproducible measuring results

Flexible at the process and in the laboratory

Automated inspection of die cast aluminium before bonding

In manufacturing processes of cast parts release agents are used. In follow-up processes such as the bonding of sealing grooves, release agent residues lead to insufficient adhesion of the bonding joint.

By inspecting the cleanliness of a sealing groove via fluorescence measurement, the quality of the bonding joint is ensured.

-

Inspection of printed circuit boards

To meet the high quality requirements of bonding and soldering processes, pads have to be free of organic contamination. By scanning the pads cleanliness can be controlled and high quality standards are ensured.

Defects can be identified at an early time and thus, rejects and costly system failures can be prevented.

Measuring principle

The measuring method uses the characteristic of organic substances to fluoresce. UV light is focused and radiated onto the surface. The contamination fluoresces. The intensity of the fluores-cence increases with the layer thickness of the contamination. The intensity is measured in RFU: Relative Fluorescence Unit.

The lower the measuring values in RFU, the cleaner the surface.

Catalogs

SITA FluoScan 3D

2 Pages

Other SITA Messtechnik products

Fluorescence Measuring and Testing Devices

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.