Contamination monitoring system ConSpectormeasurementportableautomatic

Add to favorites

Compare this product

Characteristics

- Applications

- measurement, contamination

- Configuration

- portable

- Other characteristics

- automatic, continuous

Description

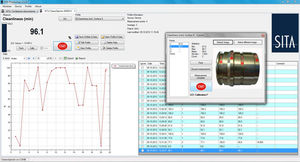

Evaluation of bath conditions depending on parts flow or bath operation time. Determination of bath contamination through fluorescence measurement.

SIMPLE

Start of measurement at the touch of one button and display of measuring result within a few seconds.

MULTIFUNCTIONAL

Mobile and hand-held measuring device to be used directly at the plant or in the laboratory. Efficient bath management through an optimization of the bath operation time.

Removing contamination off cleaning and rinsing bath in the industrial part cleaning industry ensures a long bath operation time and high parts cleanliness. The SITA ConSpector can measure the bath contamination in cleaning and rinsing baths at the plant or in the laboratory. The measuring result is available within a few seconds.

Sudden process disturbances such as the breakdown of the filter unit or a high increase of the contamination level in the bath can be immediately identified and resolved at the same time. Cleaning bath treatment measures can be carried out and controlled according to the application. The cleaning process can be carried out within allowed limit values leading to a reliable cleaning result. Controlling the rinsing steps with regard to the carry-over effect of contamination or cleaning chemicals avoids a further contamination of parts.

Examples for detectable contamination:

Cooling lubricants

Rolling oil

Grease

Deep drawing oils

Release agents

Measuring principle

The fluorescence of the bath contamination (e.g. oil drop) is excited by a UV light source.

VIDEO

Catalogs

ConSpector

4 Pages

Other SITA Messtechnik products

Fluorescence Measuring and Testing Devices

Related Searches

- Inspection system

- Measurement monitoring device

- Environmental monitoring device

- Continuous monitoring device

- Automatic monitoring device

- Measurement inspection system

- Surface inspection system

- Portable monitoring device

- In-line inspection system

- Handheld inspection system

- Thickness inspection system

- Contamination monitoring device

- Contamination inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.