- Metrology - Laboratory

- Analytical Instrumentation

- Reflection probe

- SIUI(Shantou Institute of Ultrasonic Instruments)

- Products

- Catalogs

- News & Trends

- Exhibitions

Reflection probe ultrasonicfor surface inspectioninspection

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic, reflection

- Applications

- for surface inspection

- Domain

- inspection

Description

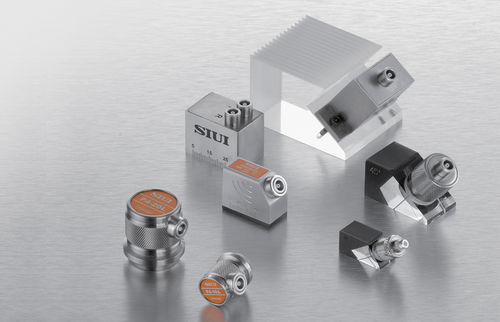

Normal Probe

Mainly used for testing defects parallel to or slightly tilted against the test surface (e.g.steel plate)

Replaceable Membrane Normal Probe

Mainly used for inspecting container flaws as well as flaws parallel to the inspected surface, applicable for checking coarse and slightly-curved surfaced objects.

Replaceable Delay Line Normal Probe

Mainly used for inspecting flaws parallel to/ near to the inspected object surface, applicablefor inspected objects with sharp edge.

If the delay line is made ofhigh-temperature material, it can also inspect high-temperature objects.

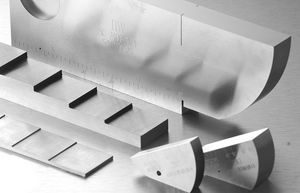

Angle Probe (Transverse Wave)

Mainly used for testing defects perpendicular to or obviously tilted against the test surface (e.g.welding line testing).

Angle Probe ( Longitudinal Wave )

Mainly used fortesting defects perpendicular to or obviously tilted against the test surface (e.g.welding line testing).

Thickness Gauge Probe

Mainly used for measuring work piece thickness.

Dual-Element Angle Probe

Mainly used for testing defects tilted against the test surface or perpendicular to the test surface.

Dual-element Normal Probe

Mainly used for testing defects parallel to or slightly tilted against the test surface (e.g.steel plate);

Much more appropriate for detecting near surface flaws than normal probes.

Immersion Probe

Mainly used in situations where the work piece and the probe do not contact directly.

It is suitable for testing work piece with rough surface and automatic testing required to increase scanning speed and shorten testing time.

Variable-angle Probe

The reflection angle can be adjusted to meet different requirements.

Other SIUI(Shantou Institute of Ultrasonic Instruments) products

Probes & Accessory

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.